Buick Encore: Diagnostic information and procedures

DTC B0012 OR B0013: Driver steering wheel air bag deployment loop

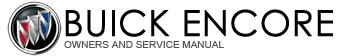

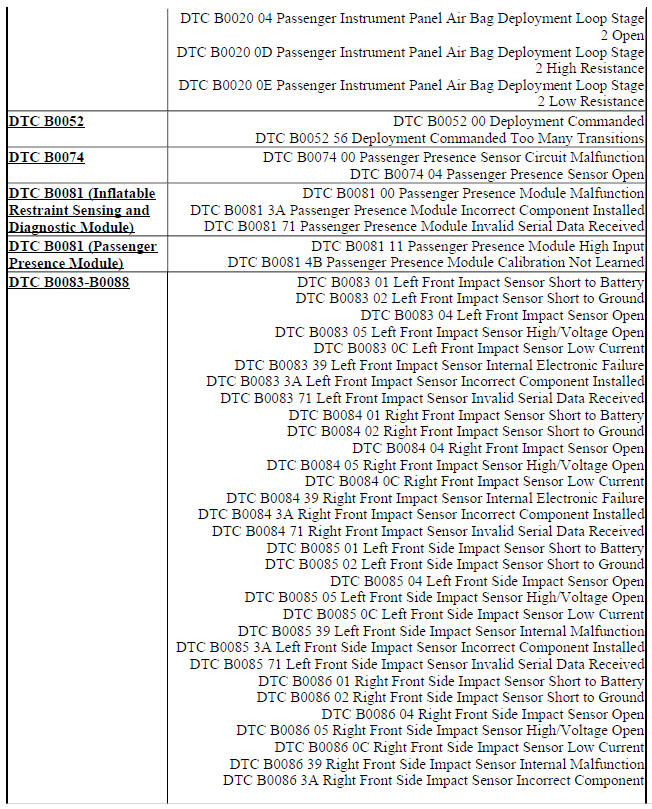

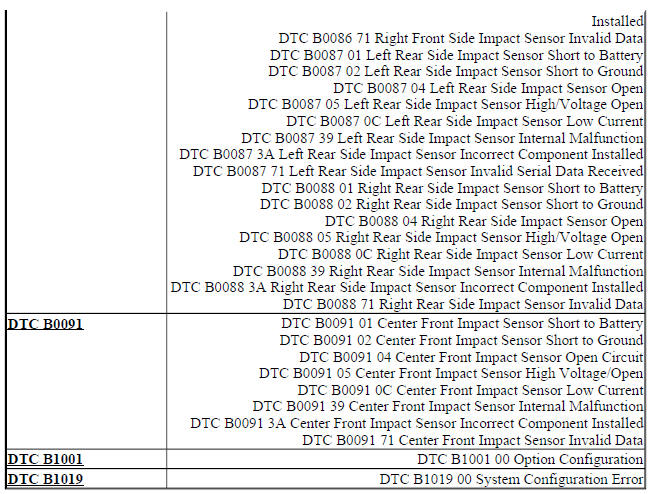

DIAGNOSTIC CODE INDEX

DTC B0012 OR B0013: DRIVER STEERING WHEEL AIR BAG DEPLOYMENT LOOP

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category

DTC Descriptors

DTC B0012 01

Driver Steering Wheel Air Bag Deployment Loop Stage 1 Short to Battery

DTC B0012 02

Driver Steering Wheel Air Bag Deployment Loop Stage 1 Short to Ground

DTC B0012 04

Driver Steering Wheel Air Bag Deployment Loop Stage 1 Open

DTC B0012 0D

Driver Steering Wheel Air Bag Deployment Loop Stage 1 High Resistance

DTC B0012 0E

Driver Steering Wheel Air Bag Deployment Loop Stage 1 Low Resistance

DTC B0013 01

Driver Steering Wheel Air Bag Deployment Loop Stage 2 Short to Battery

DTC B0013 02

Driver Steering Wheel Air Bag Deployment Loop Stage 2 Short to Ground

DTC B0013 04

Driver Steering Wheel Air Bag Deployment Loop Stage 2 Open

DTC B0013 0D

Driver Steering Wheel Air Bag Deployment Loop Stage 2 High Resistance

DTC B0013 0E

Driver Steering Wheel Air Bag Deployment Loop Stage 2 Low Resistance

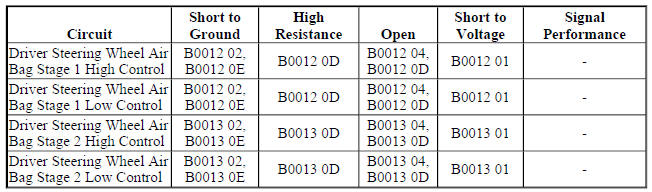

Diagnostic Fault Information

Circuit/System Description

During a frontal crash of sufficient force the inflatable restraint sensing and diagnostic module (SDM) will allow current to flow through the deployment loop in order to deploy the steering wheel air bag. The SDM performs continuous diagnostic tests on the deployment loops to check for proper circuit continuity and for shorts to ground or voltage. There are 2 shorting bars used within the steering wheel air bag coil connector which will short together both steering wheel air bag stage 1 high control circuit and steering wheel air bag stage 1 low control circuit and both steering wheel air bag stage 2 high control circuit and steering wheel air bag stage 2 low control circuit when the connector is disconnected. This will help to prevent unwanted deployment of the steering wheel air bag during servicing.

Conditions for Running the DTC

Ignition voltage is between 9-16 V.

Conditions for Setting the DTC

B0012 01 stage 1 or B0013 01 stage 2

The steering wheel air bag deployment loop is shorted to voltage for 2 seconds.

B0012 02 stage 1 or B0013 02 stage 2

The steering wheel air bag deployment loop is shorted to ground for 2 seconds.

B0012 04 stage 1 or B0013 04 stage 2

The steering wheel air bag deployment loop is open for 2 seconds.

B0012 0D stage 1 or B0013 0D stage 2

The steering wheel air bag deployment loop resistance is greater than 4.4 ohms for 2 seconds

B0012 0E stage 1 or B0013 0E stage 2

The steering wheel air bag deployment loop resistance is less than 1.7 ohms for 2 seconds.

Action Taken When the DTC Sets

- The inflatable restraint sensing and diagnostic module requests the instrument cluster to illuminate the AIR BAG indicator.

- The inflatable restraint sensing and diagnostic module will store a DTC, however if an event occurs the system will still attempt deployment.

Conditions for Clearing the DTC

- The condition for setting the DTC is no longer exists.

- A history DTC will clear once 100 malfunction-free ignition cycles have occurred.

Diagnostic Aid

NOTE: The following diagnostic aids apply for both current and history DTCs.

A worn steering wheel air bag coil can cause a repeated history DTC to set. To verify this condition, turn the steering wheel 360 degrees in one direction then back 360 degrees in the other direction, multiple times, while viewing the scan tool Deployment Loop Resistance parameters.

An incorrectly installed connector position assurance (CPA) or incorrectly seated connector can cause a shorting bar to short both control circuits together. Check the connectors and CPAs if a DTC with symptom byte 02 or 0E is set, to ensure the shorting bars are not causing the circuits to be shorted together. Shorting bars are used in the locations listed below:

- Steering wheel air bag assembly

- Steering wheel air bag coil assembly

- Inline harness connectors

- Harness side of the inflatable restraint sensing and diagnostic module connector

Terminal fretting or incorrectly seated connector can cause an open/high resistance condition. Check the circuit terminals for fretting or incorrectly seated connector if a DTC with symptom byte 04 or 0D is set.

Reference Information

Schematic Reference

SIR Schematics (Encore), SIR Schematics (Encore)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

Description and Operation

Supplemental Inflatable Restraint System Description and Operation

Electrical Information Reference

- Circuit Testing

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

- Connector Repairs

Scan Tool Reference

Control Module References for scan tool information

Special Tools

EL-38125-580 Terminal Release Tool Kit

Circuit/System Verification

NOTE:

- Refer to SIR Service Precautions.

- Inspect all terminals for damage or corrosion when disconnecting connectors. Damage or corrosion in the following requires repair or replacement of the affected component/connector

- Driver steering wheel air bag

- Driver steering wheel air bag coil

- Inflatable restraint sensing and diagnostic module

- Air bag wiring harness connector

- Inflatable restraint sensing and diagnostic module wiring harness connector

- The connector and connector position assurance (CPA) may seat independent of each other. Both the connector and CPA should seat with an audible and/or tactile click. The CPA isolates the shorting-bars within the connector allowing the deployment circuit to operate properly. Replace any CPA that is damaged or missing.

- If the condition is intermittent or cannot be duplicated, disconnect the connectors and add dielectric grease / lubricant (Nyogel 760G or equivalent, meeting GM specification 9986087). This procedure will correct the high resistance condition due to terminal fretting corrosion.

- Verify the appropriate scan tool Deployment Loop Resistance parameters stay consistently between 2.1- 4.0 ohms without any spikes or dropouts while turning the steering wheel 360 degrees in one direction then back 360 degrees in the other direction.

- If less than 2.1 ohms or greater than 4.0 ohms

Refer to Circuit/System Testing.

- If there are spikes or dropouts

Replace the X85 Steering Wheel Air Bag Coil.

- If between 2.1-4.0 ohms without any spikes or dropouts

- Verify DTC B0012 or B0013 is only set as a history DTC.

- If the DTC is set as current

Refer to Circuit/System Testing.

- If the DTC is set as history

- Verify the scan tool Deployment Loop Resistance parameters stay consistently between 2.1-4.0 ohms without any drop outs or spikes while moving the harness near each connector listed below.

- X85 Steering Wheel Air Bag Coil

- F107 Steering Wheel Air Bag

- Any inline harness connector

- K36 Inflatable Restraint Sensing and Diagnostic Module

- If the reading is erratic while moving the harness, perform the following

- Inspect each connector terminal for damage or corrosion and repair as necessary

- Apply dielectric grease / lubricant (Nyogel 760G or equivalent, meeting GM specification 9986087) to each connector terminal

- Ensure each connector and CPA is correctly seated

- If between 2.1-4.0 ohms without any spikes or dropouts

- All OK.

Circuit/System Testing

- Ignition OFF, disconnect the scan tool and disconnect the appropriate harness connector listed below at the F107 Driver Steering Wheel Air Bag.

- DTC B0012 connector X1

- DTC B0013 connector X2

- Test for greater than 25 ohms between the control circuit terminal 1 and the control circuit terminal 2.

- If 25 ohms or less

- Disconnect the X1 harness connector at the K36 Inflatable Restraint Sensing and Diagnostic Module.

NOTE: Some connectors may be equipped with shorting bars as a safety component to prevent accidental deployment. When testing on a connector with shorting bars, the shorting bars must be disabled to ensure accurate test results. Insert an appropriate pick from EL- 38125-580 and depress the shorting bars above the appropriate terminals. This will lift the shorting bar from the terminal and allow accurate test results. Take care not to damage the connector, shorting bar, or terminal when depressing the shorting bar.

- Test for infinite resistance between the two control circuits.

- If less than infinite resistance, repair the short between the two circuits.

- If infinite resistance, replace the K36 Inflatable Restraint Sensing and Diagnostic Module.

- If greater than 25 ohms

- Ignition ON.

- Test for less than 11 V between each control circuit terminal listed below and ground:

- Control circuit terminal 1

- Control circuit terminal 2

- If 11 V or greater

- Ignition OFF, disconnect the X1 harness connector at the K36 Inflatable Restraint Sensing and Diagnostic Module, ignition ON.

- Test for less than 1 V between the control circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V, replace the K36 Inflatable Restraint Sensing and Diagnostic Module.

- If less than 11 V

- Ignition OFF.

- Test for greater than 25 ohms between each control circuit terminal listed below and ground:

- Control circuit terminal 1

- Control circuit terminal 2

- If 25 ohms or less

- Disconnect the X1 harness connector at the K36 Inflatable Restraint Sensing and Diagnostic Module.

NOTE:

Some connectors may be equipped with shorting bars as a safety component to prevent accidental deployment. When testing on a connector with shorting bars, the shorting bars must be disabled to ensure accurate test results. Insert an appropriate pick from EL- 38125-580 and depress the shorting bars above the appropriate terminals. This will lift the shorting bar from the terminal and allow accurate test results. Take care not to damage the connector, shorting bar, or terminal when depressing the shorting bar.

- Test for infinite resistance between the control circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance, replace the K36 Inflatable Restraint Sensing and Diagnostic Module.

- If greater than 25 ohms

- Install a 3 A fused jumper wire between the control circuit terminal 1 and the control circuit terminal 2, ignition ON.

- Verify DTC B0012 0E or B0013 0E is set while turning the steering wheel 360 degrees in one direction then back 360 degrees in the other direction.

If DTC B0012 0E or B0013 0E is not set

- Ignition OFF, disconnect the X1 harness connector at the K36 Inflatable Restraint Sensing and Diagnostic Module.

- Test for less than 2 ohms in the K85 Steering Wheel Airbag Coil and each control circuit end to end.

- If 2 ohms or greater, replace the X85 Steering Wheel Air Bag Coil or repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K36 Inflatable Restraint Sensing and Diagnostic Module.

- If DTC B0012 0E or B0013 0E is set

- Ignition OFF, connect the harness connector at the F107 Steering Wheel Air Bag, press in the CPA (if equipped) until an audible and/or tactile click is heard.

- Ignition ON, clear DTCs. Operate the vehicle within the Conditions for Running the DTC.

- Verify DTC B0012 or B0013 is not set.

- If DTC B0012 or B0013 is set

Test or replace the F107 Steering Wheel Air Bag.

- If DTC B0012 or B0013 is not set

- All OK.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Steering Wheel Airbag Coil Replacement (Encore), Steering Wheel Airbag Coil Replacement (Encore)

- Steering Wheel Airbag Replacement (Encore), Steering Wheel Airbag Replacement (Encore) SIR/SRS Wiring Repairs

- Control Module References for inflatable restraint sensing and diagnostic module replacement, programming and setup

DTC B0014, B0021, B0031, OR B0038: Seat side air bag deployment loop

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptors

DTC B0014 01

Driver Seat Side Air Bag Deployment Loop Short to Battery

DTC B0014 02

Driver Seat Side Air Bag Deployment Loop Short to Ground

DTC B0014 04

Driver Seat Side Air Bag Deployment Loop Open

DTC B0014 0D

Driver Seat Side Air Bag Deployment Loop High Resistance

DTC B0014 0E

Driver Seat Side Air Bag Deployment Loop Low Resistance

DTC B0021 01

Passenger Seat Side Air Bag Deployment Loop Short to Battery

DTC B0021 02

Passenger Seat Side Air Bag Deployment Loop Short to Ground

DTC B0021 04

Passenger Seat Side Air Bag Deployment Loop Open

DTC B0021 0D

Passenger Seat Side Air Bag Deployment Loop High Resistance

DTC B0021 0E

Passenger Seat Side Air Bag Deployment Loop Low Resistance

DTC B0031 01

Left Rear Seat Side Air Bag Deployment Loop Short to Battery

DTC B0031 02

Left Rear Seat Side Air Bag Deployment Loop Short to Ground

DTC B0031 04

Left Rear Seat Side Air Bag Deployment Loop Open

DTC B0031 0D

Left Rear Seat Side Air Bag Deployment Loop High Resistance

DTC B0031 0E

Left Rear Seat Side Air Bag Deployment Loop Low Resistance

DTC B0038 01

Right Rear Seat Side Air Bag Deployment Loop Short to Battery

DTC B0038 02

Right Rear Seat Side Air Bag Deployment Loop Short to Ground

DTC B0038 04

Right Rear Seat Side Air Bag Deployment Loop Open

DTC B0038 0D

Right Rear Seat Side Air Bag Deployment Loop High Resistance

DTC B0038 0E

Right Rear Seat Side Air Bag Deployment Loop Low Resistance

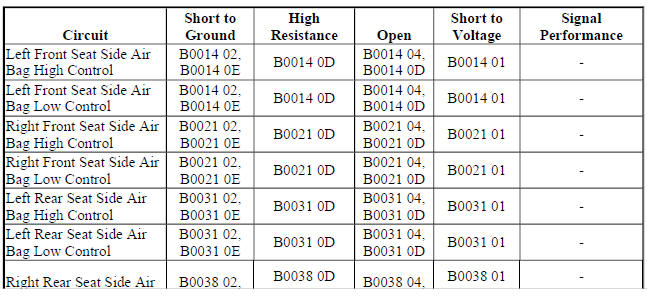

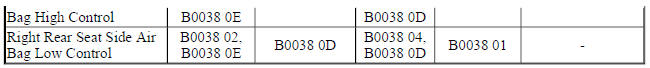

Diagnostic Fault Information

Circuit/System Description

During a side or frontal crash of sufficient force, the inflatable restraint sensing and diagnostic module (SDM) will allow current to flow through the deployment loop in order to deploy an air bag. There are 2 shorting bars used within the connector that will short the control circuits together when the connector is disconnected. This will help to prevent unwanted deployment of the air bag or retractor pretensioner during servicing.

Conditions for Running the DTC

Ignition voltage is between 9-16 V.

Conditions for Setting the DTC

B0014 01, B0021 01, B0031 01, B0038 01

The air bag control circuit is shorted to voltage for 2 seconds.

B0014 02, B0021 02, B0031 02, B0038 02

The air bag control circuit is shorted to ground for 2 seconds.

B0014 04, B0021 04, B0031 04, B0038 04

The air bag control circuit is open for 2 seconds.

B0014 0D, B0021 0D, B0031 0D, B0038 0D

The air bag deployment loop resistance is greater than 4.2 ohms for 2 seconds.

B0014 0E, B0021 0E, B0031 0E, B0038 0E

The air bag deployment loop resistance is less than 1.4 ohms for 2 seconds.

Action Taken When the DTC Sets

- The inflatable restraint sensing and diagnostic module requests the instrument cluster to illuminate the AIR BAG indicator.

- The inflatable restraint sensing and diagnostic module will store a DTC, however if an event occurs the system will still attempt deployments.

Conditions for Clearing the DTC

- The condition for setting the DTC no longer exists.

- A history DTC will clear once 100 malfunction-free ignition cycles have occurred.

Diagnostic Aid

NOTE: The following diagnostic aids apply for both current and history DTCs.

An incorrectly installed connector position assurance (CPA) or incorrectly seated connector can cause a shorting bar to short both control circuits together. Check the connectors and CPAs if a DTC with symptom byte 02 or 0E is set, to ensure the shorting bars are not causing the circuits to be shorted together. Shorting bars are used in the locations listed below:

- Front and rear seat side air bags

- Left and right roof rail air bags

- Inline harness connectors

- Harness side of the inflatable restraint sensing and diagnostic module connector

Terminal fretting or incorrectly seated connector can cause an open/high resistance condition. Check the circuit terminals for fretting or incorrectly seated connector if a DTC with symptom byte 04 or 0D is set. DTCs of deployment loops which are in the seat can occur because of stress or damage to the harness due to seat movement. Move the seat to the full extent of travel while using the scan tool to observe deployment type loop parameters.

Reference Information

Schematic Reference

SIR Schematics (Encore), SIR Schematics (Encore)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

Description and Operation

Supplemental Inflatable Restraint System Description and Operation

Electrical Information Reference

- Circuit Testing

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

- Connector Repairs

Scan Tool Reference

Control Module References for scan tool information

Special Tools

EL-38125-580 Terminal Release Tool Kit

Circuit/System Verification

NOTE:

- Refer to SIR Service Precautions.

- Inspect all terminals for damage or corrosion when disconnecting connectors. Damage or corrosion in the following requires repair or replacement of the affected component/connector.

- Seat side air bag

- Inflatable restraint sensing and diagnostic module

- All wiring harness connectors

- Inflatable restraint sensing and diagnostic module wiring harness connecto

- The connector and connector position assurance (CPA) may seat independent of each other. Both the connector and CPA should seat with an audible and/or tactile click. The CPA isolates the shorting-bars within the connector allowing the deployment circuit to operate properly.

- If the condition is intermittent or cannot be duplicated, disconnect the connectors and add dielectric grease/lubricant (Nyogel 760G or equivalent, meeting GM specification 9986087). This procedure will correct the high resistance condition due to terminal fretting corrosion.

- Verify the appropriate scan tool Deployment Loop Resistance parameters stay consistently between 2.1- 4.0 ohms without any spikes or dropouts while moving the harness near each connector.

- F106 Seat Side Air Bag

- Any inline harness connector

- K36 Inflatable Restraint Sensing and Diagnostic Module

- If less than 2.1 ohms or greater than 4.0 ohms

Refer to Circuit/System Testing.

If there are spikes or dropouts, perform the following:

- Inspect each connector terminal and harness for damage or corrosion and repair as necessary.

- Apply dielectric grease/lubricant (Nyogel 760G or equivalent, meeting GM specification 9986087) to each connector terminal.

- Ensure each connector and CPA is correctly seated.

- If between 2.1-4.0 ohms without any spikes or dropouts

- All OK

Circuit/System Testing

- Ignition OFF, scan tool disconnected, disconnect the harness connector at the appropriate F106 Seat Side Air Bag.

- Test for greater than 25 ohms between the control circuit terminals 1 and 2.

If 25 ohms or less

- Disconnect the X2 harness connector at the K36 Inflatable Restraint Sensing and Diagnostic Module.

NOTE: Some connectors may be equipped with shorting bars as a safety component to prevent accidental deployment. When testing on a connector with shorting bars, the shorting bars must be disabled to ensure accurate test results. Insert an appropriate pick from EL- 38125-580 and depress the shorting bars above the appropriate terminals. This will lift the shorting bar from the terminal and allow accurate test results. Take care not to damage the connector, shorting bar, or terminal when depressing the shorting bar.

- Test for infinite resistance between the 2 control circuits.

- If less than infinite resistance, repair the short between the 2 circuits.

- If infinite resistance, replace the K36 Inflatable Restraint Sensing and Diagnostic Module.

- If greater than 25 ohms

- Ignition ON.

- Test for less than 11 V between each control circuit terminal listed below and ground:

- Control circuit terminal 1

- Control circuit terminal 2

- If 11 V or greater

- Ignition OFF, disconnect the X2 harness connector at the K36 Inflatable Restraint Sensing and Diagnostic Module, ignition ON.

- Test for less than 1 V between the control circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V, replace the K36 Inflatable Restraint Sensing and Diagnostic Module.

- If less than 11 V

- Ignition OFF.

- Test for greater than 25 ohms between each control circuit terminal listed below and ground:

- Control circuit terminal 1

- Control circuit terminal 2

- If 25 ohms or less

- Disconnect the X2 harness connector at the K36 Inflatable Restraint Sensing and Diagnostic Module.

- Test for infinite resistance between the control circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance, replace the K36 Inflatable Restraint Sensing and Diagnostic Module.

- If greater than 25 ohms

- Install a 3 A fused jumper wire between the control circuit terminals 1 and 2, ignition ON.

- Verify DTC B0014 0E, B0021 0E, B0031 0E, or B0038 0E is set.

- If B0014 0E, B0021 0E, B0031 0E, or B0038 0E is not set

- Ignition OFF, disconnect the X2 harness connector at the K36 Inflatable Restraint Sensing and Diagnostic Module.

- Test for less than 2 ohms in each control circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K36 Inflatable Restraint Sensing and Diagnostic Module.

- If B0014 0E, B0021 0E, B0031 0E, or B0038 0E is set

- Ignition OFF, connect the harness connector at the F106 Seat Side Air Bag, press in the CPA (if equipped) until an audible and/or tactile click is heard.

- Ignition ON, clear DTCs. Operate the vehicle within the Conditions for Running the DTC.

- Verify DTC B0014, B0021, B0031, or B0038 is not set.

- If DTC B0014, B0021, B0031, or B0038 is set

Test or replace the F106 Seat Side Air Bag.

- If DTC B0014, B0021, B0031, or B0038 is not set

- All OK.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Front Seat Outboard Seat Back Airbag Replacement

- Rear Seat Bolster Airbag Replacement (AYF)

- Control Module References for inflatable restraint sensing and diagnostic module replacement, programming, and setup

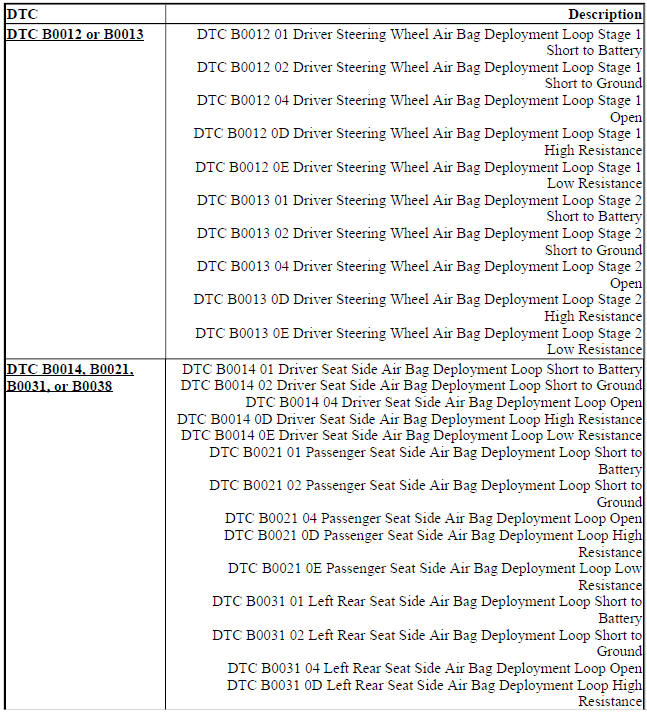

DTC B0015, B001A, B001B, OR B0022: Seat belt retractor pretensioner deployment loop

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptors

DTC B0015 01

Driver Seat Belt Retractor Pretensioner Deployment Loop Short to Battery

DTC B0015 02

Driver Seat Belt Retractor Pretensioner Deployment Loop Short to Ground

DTC B0015 04

Driver Seat Belt Retractor Pretensioner Deployment Loop Open

DTC B0015 0D

Driver Seat Belt Retractor Pretensioner Deployment Loop High Resistance

DTC B0015 0E

Driver Seat Belt Retractor Pretensioner Deployment Loop Low Resistance

DTC B001A 01

Driver Seat Belt Anchor Pretensioner Deployment Loop Short to Battery

DTC B001A 02

Driver Seat Belt Anchor Pretensioner Deployment Loop Short to Ground

DTC B001A 04

Driver Seat Belt Anchor Pretensioner Deployment Loop Open

DTC B001A 0D

Driver Seat Belt Anchor Pretensioner Deployment Loop High Resistance

DTC B001A 0E

Driver Seat Belt Anchor Pretensioner Deployment Loop Low Resistance

DTC B001B 01

Passenger Seat Belt Anchor Pretensioner Deployment Loop Short to Battery

DTC B001B 02

Passenger Seat Belt Anchor Pretensioner Deployment Loop Short to Ground

DTC B001B 04

Passenger Seat Belt Anchor Pretensioner Deployment Loop Open

DTC B001B 0D

Passenger Seat Belt Anchor Pretensioner Deployment Loop High Resistance

DTC B001B 0E

Passenger Seat Belt Anchor Pretensioner Deployment Loop Low Resistance

DTC B0022 01

Passenger Seat Belt Retractor Pretensioner Deployment Loop Short to Battery

DTC B0022 02

Passenger Seat Belt Retractor Pretensioner Deployment Loop Short to Ground

DTC B0022 04

Passenger Seat Belt Retractor Pretensioner Deployment Loop Open Circuit

DTC B0022 0D

Passenger Seat Belt Retractor Pretensioner Deployment Loop High Resistance

DTC B0022 0E

Passenger Seat Belt Retractor Pretensioner Deployment Loop Low Resistance

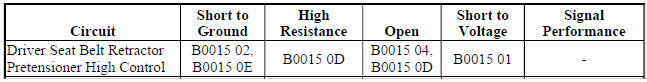

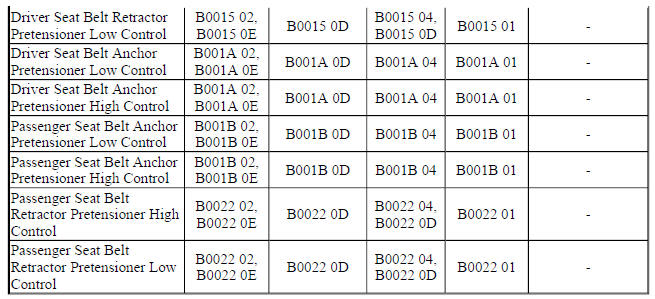

Diagnostic Fault Information

Circuit/System Description

During a side or frontal crash of sufficient force the inflatable restraint sensing and diagnostic module (SDM) will allow current to flow through the deployment loop in order to deploy an air bag or pretensioner. There are 2 shorting bars which will short the control circuits together when the connector is disconnected. This will help to prevent unwanted deployment of the air bag or pretensioner during servicing.

Conditions for Running the DTC

Ignition voltage is between 9-16 V.

Conditions for Setting the DTC

B0015 01, B001A 01, B001B 01, B0022 01

The pretensioner control circuit is shorted to voltage for 2 seconds.

B0015 02, B001A 02, B001B 02, B0022 02

The pretensioner control circuit is shorted to ground for 2 seconds.

B0015 04, B001A 04, B001B 04, B0022 04

The pretensioner control circuit is open for 2 seconds.

B0015 0D, B001A 0D, B001B 0D, B0022 0D

The pretensioner deployment loop resistance is greater than 4.2 ohms for 2 seconds.

B0015 0E, B001A 0E, B001B 0E, B0022 0E

The pretensioner deployment loop resistance is less than 1.4 ohms for 2 seconds.

Action Taken When the DTC Sets

- The Inflatable Restraint and Sensing Diagnostic Module requests the instrument cluster to illuminate the AIR BAG indicator.

- The Inflatable Restraint and Sensing Diagnostic Module will store a DTC, however if an event occurs the system will still attempt deployments.

Conditions for Clearing the DTC

- The condition for setting the DTC no longer exists.

- A history DTC will clear once 100 malfunction-free ignition cycles have occurred.

Diagnostic Aid

NOTE: The following diagnostic aids apply for both current and history DTCs.

An incorrectly installed connector position assurance (CPA) or incorrectly seated connector can cause a shorting bar to short both control circuits together. Check the connectors and CPAs if a DTC with symptom byte 02 or 0E is set, to ensure the shorting bars are not causing the circuits to be shorted together. Shorting bars are used in the locations listed below:

- Driver and passenger anchor or retractor pretensioners

- Inline harness connectors

- Harness side of the Inflatable Restraint and Sensing Diagnostic Module connector

Terminal fretting or incorrectly seated connectors can cause an open/high resistance condition. Check the circuit terminals for fretting or incorrectly seated connector if a DTC with symptom byte 04 or 0D is set. DTCs of deployment loops which are in the seat can occur because of stress or damage to the harness due to seat movement. Move the seat to the full extent of travel while using the scan tool to observe deployment type loop parameters.

Reference Information

Schematic Reference

SIR Schematics (Encore), SIR Schematics (Encore)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

Description and Operation

Supplemental Inflatable Restraint System Description and Operation

Electrical Information Reference

- Circuit Testing

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

- Connector Repairs

Scan Tool Reference

Control Module References for scan tool information

Special Tools

EL-38125-580 Terminal Release Tool Kit

Circuit/System Verification

NOTE:

- Refer to SIR Service Precautions.

- Inspect all terminals for damage or corrosion when disconnecting connectors. Damage or corrosion in the following requires repair or replacement of the affected component/connector.

- Seat belt retractor pretensioner

- Inflatable restraint and sensing diagnostic module

- Seat belt retractor pretensioner wiring harness connector

- Passenger instrument panel air bag wiring harness connector

- Seat side air bag wiring harness connector

- Roof rail air bag wiring harness connector

- Inflatable Restraint and Sensing Diagnostic Module wiring harness connector

- The connector and connector position assurance (CPA) may seat independent of each other. Both the connector and CPA should seat with an audible and/or tactile click. The CPA isolates the shorting-bars within the connector allowing the deployment circuit to operate properly.

- If the condition is intermittent or cannot be duplicated, disconnect the connectors and add dielectric grease / lubricant (Nyogel 760G or equivalent, meeting GM specification 9986087). This procedure will correct the high resistance condition due to terminal fretting corrosion.

- Verify the appropriate scan tool Deployment Loop Resistance parameters stay consistently between 2.1-4.0 ohms without any spikes or dropouts while moving the harness near each connector listed below:

- F112 Seat Belt Retractor Pretensioner

- F113 Seat Belt Anchor Pretensioner

- Any inline harness connector

- K36 Inflatable Restraint and Sensing Diagnostic Module

- If less than 2.1 ohms or greater than 4.0 ohms

Refer to Circuit/System Testing.

- If there are spikes or dropouts, perform the following

- Inspect each connector terminal and harness for damage or corrosion and repair as necessary

- Ensure each connector and CPA is correctly seated.

- If between 2.1-4.0 ohms without any spikes or dropouts

- All OK

Circuit/System Testing

- Ignition OFF, scan tool disconnected, disconnect the appropriate harness connector listed below. It may take up to 2 min for all vehicle systems to power down.

- F112 Seat Belt Retractor Pretensioner

- F113 Seat Belt Anchor Pretensioner

- Test for greater than 25 ohms between the control circuit terminals 1 and 2.

- If 25 ohms or less

- Disconnect the X2 harness connector at the K36 Inflatable Restraint and Sensing Diagnostic Module.

NOTE:

Some connectors may be equipped with shorting bars as a safety component to prevent accidental inflator deployment. When testing on a connector with shorting bars, the shorting bars must be disabled to ensure accurate test results. Insert an appropriate pick from EL-38125-580 and depress the shorting bars above the appropriate terminals. This will lift the shorting bar from the terminal and allow accurate test results. Take care not to damage the connector, shorting bar, or terminal when depressing the shorting bar.

- Test for infinite resistance between the two control circuits.

- If less than infinite resistance, repair the short between the two circuits.

- If infinite resistance, replace the K36 Inflatable Restraint and Sensing Diagnostic Module.

- If greater than 25 ohms

- Ignition ON.

- Test for less than 11 V between each control circuit terminal listed below and ground:

- Control circuit terminal 1

- Control circuit terminal 2

- If 11 V or greater

- Ignition OFF, disconnect the X2 harness connector at the K36 Inflatable Restraint and Sensing Diagnostic Module, ignition ON

- Test for less than 1 V between the control circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V, replace the K36 Inflatable Restraint and Sensing Diagnostic Module.

- If less than 11 V

- Ignition OFF.

- Test for greater than 25 ohms between each control circuit terminal listed below and ground:

- Control circuit terminal 1

- Control circuit terminal 2

- If 25 ohms or less

- Disconnect the X2 harness connector at the K36 Inflatable Restraint and Sensing Diagnostic Module.

- Test for infinite resistance between the control circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance, replace the K36 Inflatable Restraint and Sensing Diagnostic Module.

- If greater than 25 ohms

- Install a 3 A fused jumper wire between the control circuit terminals 1 and 2, ignition ON.

- Verify DTC B0015 0E, B001A 0E, B001B 0E, or B0022 0E is set.

If B0015 0E, B001A 0E, B001B 0E, or B0022 0E is not set

- Ignition OFF, disconnect the X2 harness connector at the K36 Inflatable Restraint and Sensing Diagnostic Module.

- Test for less than 2 ohms in each control circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K36 Inflatable Restraint and Sensing Diagnostic Module.

- If B0015 0E, B001A 0E, B001B 0E, or B0022 0E is set

- Ignition OFF, connect the harness connector at the F112 Seat Belt Retractor Pretensioner or F113 Seat Belt Anchor Pretensioner, press in the CPA (if equipped) until an audible and/or tactile click is heard.

- Ignition ON, clear DTCs. Operate the vehicle within the Conditions for Running the DTC.

- Verify DTC B0015, B001A, B001B, or B0022 is not set.

- If DTC B0015, B001A, B001B, or B0022 is set

Replace the F112 Seat Belt Retractor Pretensioner or F113 Seat Belt Anchor Pretensioner.

- If DTC B0015, B001A, B001B, or B0022 is not set

- All OK.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Front Seat Belt Anchor Plate Tensioner Replacement

- Front Seat Belt Retractor Replacement (With A69)

- SIR/SRS Wiring Repairs

- Control Module References for Inflatable Restraint and Sensing Diagnostic Module replacement, programming and setup

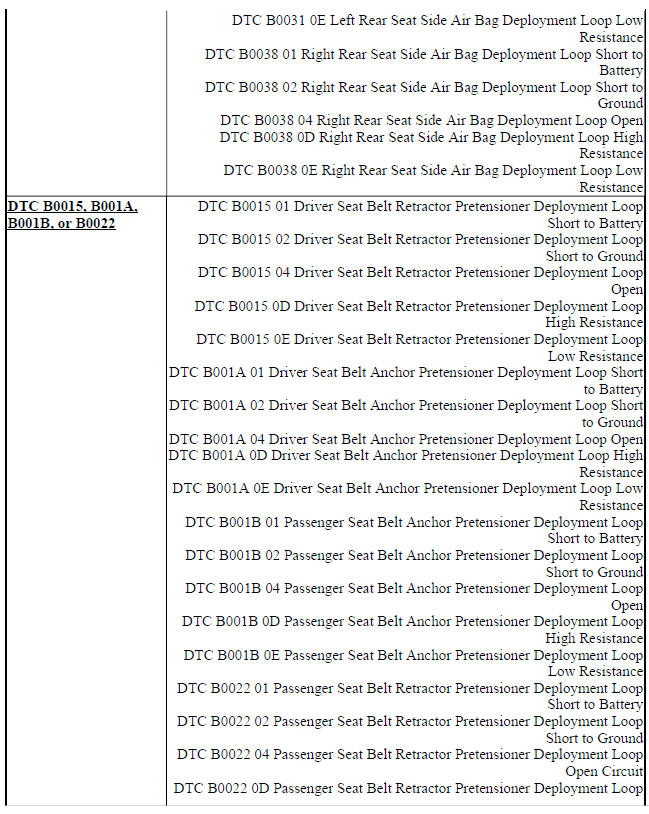

DTC B0016, B0018, B0023, OR B0025: Roof rail air bag deployment loop

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptors

DTC B0016 01

Left Roof Rail Air Bag Deployment Loop Short to Battery

DTC B0016 02

Left Roof Rail Air Bag Deployment Loop Short to Ground

DTC B0016 04

Left Roof Rail Air Bag Deployment Loop Open

DTC B0016 0D

Left Roof Rail Air Bag Deployment Loop High Resistance

DTC B0016 0E

Left Roof Rail Air Bag Deployment Loop Low Resistance

DTC B0023 01

Right Roof Rail Air Bag Deployment Loop Short to Battery

DTC B0023 02

Right Roof Rail Air Bag Deployment Loop Short to Ground

DTC B0023 04

Right Roof Rail Air Bag Deployment Loop Open

DTC B0023 0D

Right Roof Rail Air Bag Deployment Loop High Resistance

DTC B0023 0E

Right Roof Rail Air Bag Deployment Loop Low Resistance

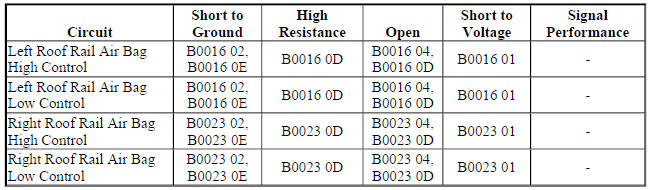

Diagnostic Fault Information

Circuit/System Description

During a side or frontal crash of sufficient force the inflatable restraint sensing and diagnostic module (SDM) will allow current to flow through the deployment loop in order to deploy an air bag or pretensioner. There are 2 shorting bars which will short together control circuits, when the connector is disconnected. This will help to prevent unwanted deployment of the air bag or pretensioner during servicing.

Conditions for Running the DTC

Ignition voltage is between 9-16 V.

Conditions for Setting the DTC

B0016 01, B0023 01

The air bag control circuit is shorted to voltage for 2 seconds.

B0016 02, B0023 02

The air bag control circuit is shorted to ground for 2 seconds.

B0016 04, B0023 04

The air bag control circuit is open for 2 seconds.

B0016 0D, B0023 0D

The air bag deployment loop resistance is greater than 4.2 ohms for 2 seconds.

B0016 0E, B0023 0E

The air bag deployment loop resistance is less than 1.4 ohms for 2 seconds

Action Taken When the DTC Sets

- The inflatable restraint sensing and diagnostic module requests the instrument cluster to illuminate the AIR BAG indicator.

- The inflatable restraint sensing and diagnostic module will store a DTC, however if an event occurs the system will still attempt deployments.

Conditions for Clearing the DTC

- The condition for setting the DTC no longer exists.

- A history DTC will clear once 100 malfunction-free ignition cycles have occurred.

Diagnostic Aid

NOTE: The following diagnostic aids apply for both current and history DTCs.

An incorrectly installed connector position assurance (CPA) or incorrectly seated connector can cause a shorting bar to short both control circuits together. Check the connectors and CPAs if a DTC with symptom byte 02 or 0E is set, to ensure the shorting bars are not causing the circuits to be shorted together. Shorting bars are used in the locations listed below:

- Left and right roof rail air bags

- Inline harness connectors

- Harness side of the inflatable restraint sensing and diagnostic module connector

Terminal fretting or incorrectly seated connectors can cause an open/high resistance condition. Check the circuit terminals for fretting or incorrectly seated connector if a DTC with symptom byte 04 or 0D is set. DTCs of deployment loops which are in the seat DTC can occur because of stress or damage to the harness due to seat movement. Move the seat to the full extent of travel while using the scan tool to observe deployment type loop parameters.

Reference Information

Schematic Reference

SIR Schematics (Encore), SIR Schematics (Encore)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

Description and Operation

Supplemental Inflatable Restraint System Description and Operation

Electrical Information Reference

- Circuit Testing

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

- Connector Repairs

Scan Tool Reference

Control Module References for scan tool information

Special Tools

EL-38125-580 Terminal Release Tool Kit

Circuit/System Verification

NOTE:

- Refer to SIR Service Precautions.

- Inspect all terminals for damage or corrosion when disconnecting connectors. Damage or corrosion in the following requires repair or replacement of the affected component/connector.

- Roof rail air bag

- Roof rail air bag wiring harness connector

- Inflatable restraint sensing and diagnostic module

- Inflatable restraint sensing and diagnostic module wiring harness connector

- The connector and connector position assurance (CPA) may seat independent of each other. Both the connector and CPA should seat with an audible and/or tactile click. The CPA isolates the shorting-bars within the connector allowing the deployment circuit to operate properly.

- If the condition is intermittent or cannot be duplicated, disconnect the connectors and add dielectric grease / lubricant (Nyogel 760G or equivalent, meeting GM specification 9986087). This procedure will correct the high resistance condition due to terminal fretting corrosion

- Verify DTC B0016 or B0023 is only set as a history DTC

- If the DTC is set as current

Refer to Circuit/System Testing.

- If the DTC is set as history

- Verify DTC B0016 or B0023 is only set as a history DTC while moving the harness near each connector listed below:

- F105L Roof Rail Air Bag - Left

- F105R Roof Rail Air Bag - Right

- Any inline harness connector

- K36 inflatable restraint sensing and diagnostic module

- If the DTC is set as current while moving the harness, perform the following

- Inspect each connector terminal for damage or corrosion and repair as necessary Apply dielectric grease / lubricant (Nyogel 760G or equivalent, meeting GM specification 9986087) to each connector terminal

- Ensure each connector and CPA is correctly seated

- If the DTC is set as history

- All OK.

Circuit/System Testing

- Ignition OFF. Scan tool disconnected. Disconnect the harness connector at the appropriate F105 Roof Rail Air Bag. It may take up to 2 min for all vehicle systems to power down.

- Test for greater than 25 ohms between the control circuit terminals 1 and 2.

- If 25 ohms or less

- Disconnect the X2 harness connector at the K36 Inflatable Restraint Sensing and Diagnostic Module.

NOTE: Some connectors may be equipped with shorting bars as a safety component to prevent accidental inflator deployment. When testing on a connector with shorting bars, the shorting bars must be disabled to ensure accurate test results. Insert an appropriate pick from EL-38125-580 and depress the shorting bars above the appropriate terminals. This will lift the shorting bar from the terminal and allow accurate test results. Take care not to damage the connector, shorting bar, or terminal when depressing the shorting bar.

- Test for infinite resistance between the two control circuits.

- If less than infinite resistance, repair the short between the two circuits.

- If infinite resistance, replace the K36 Inflatable Restraint Sensing and Diagnostic Module.

- If greater than 25 ohms

- Ignition ON.

- Test for less than 11 V between the control circuit terminals listed below and ground:

- Control circuit terminal 1

- Control circuit terminal 2

- If 11 V or greater

- Ignition OFF. Disconnect the X2 harness connector at the K36 Inflatable Restraint Sensing and Diagnostic Module. Ignition ON.

- Test for less than 1 V between the control circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V, replace the K36 Inflatable Restraint Sensing and Diagnostic Module.

- If less than 11 V

- Ignition OFF.

- Test for greater than 25 ohms between the control circuit terminals listed below and ground:

- Control circuit terminal 1

- Control circuit terminal 2

- If 25 ohms or less

- Disconnect the X2 harness connector at the K36 Inflatable Restraint Sensing and Diagnostic Module.

- Test for infinite resistance between the control circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance, replace the K36 Inflatable Restraint Sensing and Diagnostic Module.

- If greater than 25 ohms

- Ignition OFF. Install a 3 A fused jumper wire between the control circuit terminals 1 and 2. Ignition ON.

- Verify DTC B0016 0E or B0023 0E is set

- If DTC B0016 0E or B0023 0E is not set

- Ignition OFF. Disconnect the X2 harness connector at the K36 Inflatable Restraint Sensing and Diagnostic Module.

- Test for less than 2 ohms in each control circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K36 inflatable restraint sensing and diagnostic module.

- If DTC B0016 0E or B0023 0E is set

- Ignition OFF, connect the harness connector at the F105 Roof Rail Air Bag, press in the CPA (if equipped) until an audible and/or tactile click is heard.

- Ignition ON, clear DTCs. Operate the vehicle within the Conditions for Running the DTC.

- Verify DTC B0016 or B0023 is not set.

- If DTC B0016 or B0023 is set

Test or replace the F105 Roof Rail Air Bag.

- If DTC B0016 or B0023 is not set

- All OK.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Airbag Roof Side Rail Module Replacement (Encore), Airbag Roof Side Rail Module Replacement (Encore)

- SIR/SRS Wiring Repairs

- Control Module References for inflatable restraint sensing and diagnostic module replacement, programming and setup

DTC B0017 OR B0024: Knee air bag deployment loop

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptors

DTC B0017 01

Driver Knee Air Bag Deployment Loop Short to Battery

DTC B0017 02

Driver Knee Air Bag Deployment Loop Short to Ground

DTC B0017 04

Driver Knee Air Bag Deployment Loop Open

DTC B0017 0D

Driver Knee Air Bag Deployment Loop High Resistance

DTC B0017 0E

Driver Knee Air Bag Deployment Loop Low Resistance

DTC B0024 01

Passenger Knee Air Bag Deployment Loop Short to Battery

DTC B0024 02

Passenger Knee Air Bag Deployment Loop Short to Battery

DTC B0024 04

Passenger Knee Air Bag Deployment Loop Open

DTC B0024 0D

Passenger Knee Air Bag Deployment Loop High Resistance

DTC B0024 0E

Passenger Knee Air Bag Deployment Loop Low Resistance

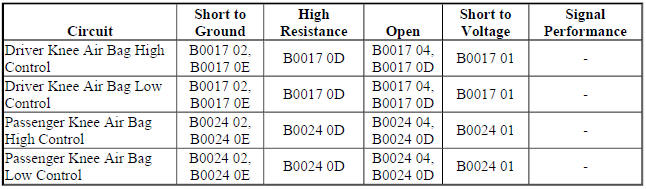

Diagnostic Fault Information

Circuit/System Description

During a side or frontal crash of sufficient force the Inflatable Restraint Sensing and Diagnostic Module (SDM) will allow current to flow through the deployment loop in order to deploy an air bag. There are two shorting bars used within the connector that will short together the control circuits, when the connector is disconnected.

This will help to prevent unwanted deployment of the air bag or retractor pretensioner during servicing.

Conditions for Running the DTC

Ignition voltage is between 9-16 V.

Conditions for Setting the DTC

B0017 01, B0024 01

The air bag control circuit is shorted to voltage for 2 seconds.

B0017 02, B0024 02

The air bag control circuit is shorted to ground for 2 seconds.

B0017 04, B0024 04

The air bag control circuit is open for 2 seconds.

B0017 0D, B0024 0D

The air bag deployment loop resistance is greater than 4.2 ohms for 2 seconds.

B0017 0E, B0024 0E

The air bag deployment loop resistance is less than 1.4 ohms for 2 seconds.

Action Taken When the DTC Sets

- The Inflatable Restraint Sensing and Diagnostic Module requests the instrument cluster to illuminate the AIR BAG indicator.

- The Inflatable Restraint Sensing and Diagnostic Module will store a DTC, however if an event occurs the system will still attempt deployments.

Conditions for Clearing the DTC

- The condition for setting the DTC no longer exists.

- A history DTC will clear once 100 malfunction-free ignition cycles have occurred.

Diagnostic Aid

NOTE: The following diagnostic aids apply for both current and history DTCs.

An incorrectly installed connector position assurance (CPA) or incorrectly seated connector can cause a shorting bar to short both control circuits together. Check the connectors and CPAs if a DTC with symptom byte 02 or 0E is set, to ensure the shorting bars are not causing the circuits to be shorted together. Shorting bars are used in the locations listed below:

- Driver and passenger knee air bags

- Inline harness connectors

- Harness side of the inflatable restraint sensing and diagnostic module connector

Terminal fretting or incorrectly seated connector can cause an open/high resistance condition. Check the circuit terminals for fretting or incorrectly seated connector if a DTC with symptom byte 04 or 0D is set.

Reference Information

Schematic Reference

SIR Schematics (Encore), SIR Schematics (Encore)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

Component Connector End Views (Encore) , Component Connector End Views (Encore)

Description and Operation

Supplemental Inflatable Restraint System Description and Operation

Electrical Information Reference

- Circuit Testing

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

- Connector Repairs

Scan Tool Reference

Control Module References for scan tool information

Special Tools

EL-38125-580 Terminal Release Tool Kit

Circuit/System Verification

NOTE:

- Refer to SIR Service Precautions.

- Inspect all terminals for damage or corrosion when disconnecting connectors. Damage or corrosion in the following requires repair or replacement of the affected component/connector.

- Knee air bag

- Inflatable restraint sensing and diagnostic module

- All wiring harness connectors

- Inflatable restraint sensing and diagnostic module wiring harness connector

- The connector and connector position assurance (CPA) may seat independent of each other. Both the connector and CPA should seat with an audible and/or tactile click. The CPA isolates the shorting-bars within the connector allowing the deployment circuit to operate properly.

- If the condition is intermittent or cannot be duplicated, disconnect the connectors and add dielectric grease/lubricant (Nyogel 760G or equivalent, meeting GM specification 9986087). This procedure will correct the high resistance condition due to terminal fretting corrosion.

- Verify the scan tool Deployment Loop Resistance parameters stay consistently between 2.1 and 4.0 ohms without any spikes or dropouts while moving the harness near each connector listed below:

- F114D Knee Air Bag - Driver

- F114P Knee Air Bag - Passenger

- Any inline harness connector

- K36 Inflatable Restraint Sensing and Diagnostic Module

- If less than 2.1 or greater than 4.0 ohms

Refer to Circuit/System Testing.

- If there are spikes or dropouts, perform the following:

- Inspect each connector terminal and harness for damage or corrosion and repair as necessary.

- Apply dielectric grease/lubricant (Nyogel 760G or equivalent, meeting GM specification 9986087) to each connector terminal

- Ensure each connector and CPA is correctly seated

- If between 2.1 and 4.0 ohms without any spikes or dropouts

- All OK

Circuit/System Testing

- Ignition OFF, disconnect the scan tool and disconnect the harness connector at the appropriate F114 Knee Air Bag.

- Test for greater than 25 ohms between the control circuit terminals 1 and 2.

- If 25 ohms or less

- Disconnect the X1 harness connector at the K36 Inflatable Restraint Sensing and Diagnostic Module.

NOTE: Some connectors may be equipped with shorting bars as a safety component to prevent accidental inflator deployment. When testing on a connector with shorting bars, the shorting bars must be disabled to ensure accurate test results. Insert an appropriate pick from EL-38125-580 and depress the shorting bars above the appropriate terminals. This will lift the shorting bar from the terminal and allow accurate test results. Take care not to damage the connector, shorting bar, or terminal when depressing the shorting bar.

- Test for infinite resistance between the 2 control circuits.

- If less than infinite resistance, repair the short between the 2 circuits.

- If infinite resistance, replace the K36 Inflatable Restraint Sensing and Diagnostic Module.

- If greater than 25 ohms

- Ignition ON.

- Test for less than 11 V between the control circuit terminals listed below and ground:

- Control circuit terminal 1

- Control circuit terminal 2

- If 11 V or greater

- Ignition OFF, disconnect the X1 harness connector at the K36 Inflatable Restraint Sensing and Diagnostic Module, ignition ON.

- Test for less than 1 V between the control circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V, replace the K36 Inflatable Restraint Sensing and Diagnostic Module.

- If less than 11 V

- Ignition OFF.

- Test for greater than 25 ohms between the control circuit terminals listed below and ground:

- Control circuit terminal 1

- Control circuit terminal 2

- If 25 ohms or less

- Disconnect the X1 harness connector at the K36 Inflatable Restraint Sensing and Diagnostic Module.

- Test for infinite resistance between the control circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance, replace the K36 Inflatable Restraint Sensing and Diagnostic Module.

- If greater than 25 ohms

- Install a 3 A fused jumper wire between the control circuit terminals 1 and 2, ignition ON.

- Verify DTC B0017 0E or B0024 0E is set

- If B0017 0E or B0024 0E is not set

- Ignition OFF, disconnect the X1 harness connector at the K36 Inflatable Restraint Sensing and Diagnostic Module.

- Test for less than 2 ohms in each control circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K36 Inflatable Restraint Sensing and Diagnostic Module.

- If B0017 0E or B0024 0E is set

- Ignition OFF, connect the harness connector at the F114 Knee Air Bag, press in the CPA (if equipped) until an audible and/or tactile click is heard.

- Ignition ON, clear DTCs. Operate the vehicle within the Conditions for Running the DTC.

- Verify DTC B0017 or B0024 is not set.

- If DTC B0017 or B0024 is set

Replace the appropriate F114 Knee Air Bag.

- If DTC B0017 or B0024 is not set

- All OK.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Instrument Panel Lower Airbag Replacement - Driver Side (AYF)

- Instrument Panel Lower Airbag Replacement - Passenger Side (AYF)

- Control Module References for K36 Inflatable Restraint Sensing and Diagnostic Module replacement, programming, and setup

DTC B0019 OR B0020 (WITHOUT AY0 OR AYF): Passenger instrument panel air bag deployment loop

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptors

DTC B0019 01

Passenger Instrument Panel Air Bag Deployment Loop Stage 1 Short to Battery

DTC B0019 02

Passenger Instrument Panel Air Bag Deployment Loop Stage 1 Short to Ground

DTC B0019 04

Passenger Instrument Panel Air Bag Deployment Loop Stage 1 Open

DTC B0019 0D

Passenger Instrument Panel Air Bag Deployment Loop Stage 1 High Resistance

DTC B0019 0E

Passenger Instrument Panel Air Bag Deployment Loop Stage 1 Low Resistance

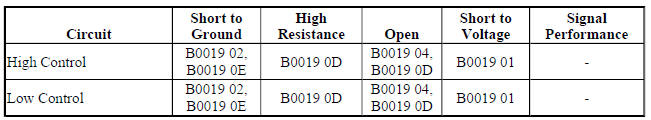

Diagnostic Fault Information

Circuit/System Description

During a side or frontal crash of sufficient force the inflatable restraint sensing and diagnostic module (SDM) will allow current to flow through the deployment loop in order to deploy an air bag or pretensioner. There is a shorting bar which will short together the control circuits, when the connector is disconnected. This will help to prevent unwanted deployment of the air bag or pretensioner during servicing.

Conditions for Running the DTC

Ignition voltage is between 9-16 V.

Conditions for Setting the DTC

B0019 01

The air bag control circuit is shorted to voltage for 2 seconds.

B0019 02

The air bag control circuit is shorted to ground for 2 seconds.

B0019 04

The air bag control circuit is open for 2 seconds.

B0019 0D

The air bag deployment loop resistance is greater than 4.2 ohms for 2 seconds.

B0019 0E

The air bag deployment loop resistance is less than 1.4 ohms for 2 seconds.

Action Taken When the DTC Sets

- The SDM requests the instrument cluster to illuminate the AIR BAG indicator.

- The SDM will store a DTC, however if an event occurs the system will still attempt deployments

Conditions for Clearing the DTC

- The condition for setting the DTC no longer exists.

- A history DTC will clear once 100 malfunction-free ignition cycles have occurred.

Diagnostic Aid

NOTE: The following diagnostic aids apply for both current and history DTCs.

An incorrectly installed connector position assurance (CPA) or incorrectly seated connector can cause a shorting bar to short both control circuits together. Check the connectors and CPAs if a DTC with symptom byte 02 or 0E is set, to ensure the shorting bars are not causing the circuits to be shorted together. Shorting bars are used in the locations listed below:

- Passenger instrument panel air bag

- Inline harness connectors

- Harness side of the SDM connector

Terminal fretting or incorrectly seated connectors can cause an open/high resistance condition. Check the circuit terminals for fretting or incorrectly seated connector if a DTC with symptom byte 04 or 0D is set. DTCs of deployment loops which are in the seat can occur because of stress or damage to the harness due to seat movement. Move the seat to the full extent of travel while using the scan tool to observe deployment type loop parameters.

Reference Information

Schematic Reference

SIR Schematics (Encore), SIR Schematics (Encore)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

Description and Operation

Supplemental Inflatable Restraint System Description and Operation

Electrical Information Reference

- Circuit Testing

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

- Connector Repairs

Scan Tool Reference

Control Module References for scan tool information

Special Tools

EL-38125-580 Terminal Release Tool Kit

Circuit/System Verification

NOTE: Refer to SIR Service Precautions.

Inspect all terminals for damage or corrosion when disconnecting connectors.

Damage or corrosion in the following requires repair or replacement of the affected component/connector.

- Seat belt retractor pretensioner

- Passenger instrument panel air bag

- Seat side air bag

- Roof rail air bag

- Inflatable restraint sensing and diagnostic module

- Seat belt retractor pretensioner wiring harness connector

- Passenger instrument panel air bag wiring harness connector

- Seat side air bag wiring harness connector

- Roof rail air bag wiring harness connector

- Inflatable restraint sensing and diagnostic module wiring harness connector

NOTE:

The connector and connector position assurance (CPA) may seat independent of each other. Both the connector and CPA should seat with an audible and/or tactile click. The CPA isolates the shorting-bars within the connector allowing the deployment circuit to operate properly.

If the condition is intermittent or cannot be duplicated, disconnect the connectors and add dielectric grease / lubricant (Nyogel 760G or equivalent, meeting GM specification 9986087). This procedure will correct the high resistance condition due to terminal fretting corrosion.

- Verify the scan tool Deployment Loop Resistance 1 parameter stay consistently between 2.1 and 4.0 ohms without any spikes or dropouts while moving the harness near each connector listed below:

- F105 Passenger Instrument Panel Air Bag

- Any inline harness connector

- K36 Inflatable Restraint Sensing and Diagnostic Module

- If less than 2.1 or greater than 4.0 ohms

Refer to Circuit/System Testing.

- If there are spikes or dropouts, perform the following

- Inspect each connector terminal and harness for damage or corrosion and repair as necessary

- Apply dielectric grease / lubricant (Nyogel 760G or equivalent, meeting GM specification 9986087) to each connector terminal

- Insure each connector and CPA is correctly seated.

- If within 2.1 and 4.0 ohms without any spikes or dropouts

- All OK

Circuit/System Testing

- Ignition OFF. Scan tool disconnected. Disconnect the X207 inline harness connector for the F105 Passenger Instrument Panel Air Bag. It may take up to 2 minutes for all vehicle systems to power down.

- Test for greater than 25 ohms between the X207 control circuit terminal 1 and 2 on the K36 Inflatable Restraint Sensing and Diagnostic Module side of the connector.

- If 25 ohms or less

- Disconnect the X1 harness connector at the K36 Inflatable Restraint Sensing and Diagnostic Module.

NOTE:

- Some connectors may be equipped with shorting bars as a safety component to prevent accidental inflator deployment. When testing on a connector with shorting bars, the shorting bars must be disabled to ensure accurate test results. Insert an appropriate pick from EL-38125-580 and depress the shorting bars above the appropriate terminals. This will lift the shorting bar from the terminal and allow accurate test results. Take care not to damage the connector, shorting bar, or terminal when depressing the shorting bar.

- Test for infinite resistance between the two control circuits.

- If less than infinite resistance, repair the short between the two circuits.

- If infinite resistance, replace the K36 Inflatable Restraint Sensing and Diagnostic Module

- If greater than 25 ohms

- Ignition ON.

- Test for less than 11 V between the control circuit terminals listed below and ground:

- X207 control circuit terminal 1

- X207 control circuit terminal 2

- If 11 V or greater

- Ignition OFF. Disconnect the harness connector at the K36 Inflatable Restraint Sensing and Diagnostic Module. Ignition ON.

- Test for less than 1 V between the control circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V, replace the K36 Inflatable Restraint Sensing and Diagnostic Module.

- If less than 11 V

- Ignition OFF.

- Test for greater than 25 ohms between the control circuit terminals listed below and ground:

- X207 control circuit terminal 1

- X207 control circuit terminal 2

- If 25 ohms or less

- Disconnect the X1 harness connector at the K36 Inflatable Restraint Sensing and Diagnostic Module.

- Test for infinite resistance between the control circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance, replace the K36 Inflatable Restraint Sensing and Diagnostic Module.

- If greater than 25 ohms

- Install a 3 A fused jumper wire between the F105 Passenger Instrument Panel Air Bag X207 control circuit terminals 1 and 2. Ignition ON.

- Verify DTC B0019 0E is set.

- If B0019 0E is not set

- Ignition OFF. Disconnect the harness connector at the K36 Inflatable Restraint Sensing and Diagnostic Module.

- Test for less than 2 ohms in each control circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K36 Inflatable Restraint Sensing and Diagnostic Module

- If B0019 0E is set

- Ignition OFF. Reconnect inline harness connector X207. Disconnect the F105 Passenger Instrument Panel Air Bag harness connector. Ignition ON.

- Test for less than 11 V between the control circuit terminals listed below and ground:

- F105 Passenger Instrument Panel Air Bag control circuit terminal 1

- F105 Passenger Instrument Panel Air Bag control circuit terminal 2

- If 11 V or greater

Repair the short to voltage on the circuit.

- If less than 11 V

- Ignition OFF.

- Test for greater than 25 ohms between the control circuit terminals listed below and ground:

- F105 Passenger Instrument Panel Air Bag control circuit terminal 1

- F105 Passenger Instrument Panel Air Bag control circuit terminal 2

- If 25 ohms or less

Repair the short to ground on the circuit.

- If greater than 25 ohms

- Install a 3 A fused jumper wire between the F105 Passenger Instrument Panel Air Bag X207 control circuit terminals 1 and 2. Ignition ON.

- Verify the scan tool Deployment Loop Resistance parameter is less than 2 ohms.

- If greater than 2 ohms

Repair the open/high resistance in the circuit between the F105 Passenger Instrument Panel Air Bag connector and the X207 inline harness connector.

- If less than 2 ohms

- Ignition OFF, connect the harness connector at the F105 Passenger Instrument Panel Air Bag, press in the CPA (if equipped) until an audible and/or tactile click is heard.

- Ignition ON, clear DTCs. Operate the vehicle within the Conditions for Running the DTC.

- Verify DTC B0019 is not set.

- If DTC B0019 is set

Replace the F105 Passenger Instrument Panel Air Bag.

- If DTC B0019 is not set

- All OK.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Airbag Instrument Panel Module Replacement

- SIR/SRS Wiring Repairs

- Control Module References for inflatable restraint sensing and diagnostic module replacement, programming and setup

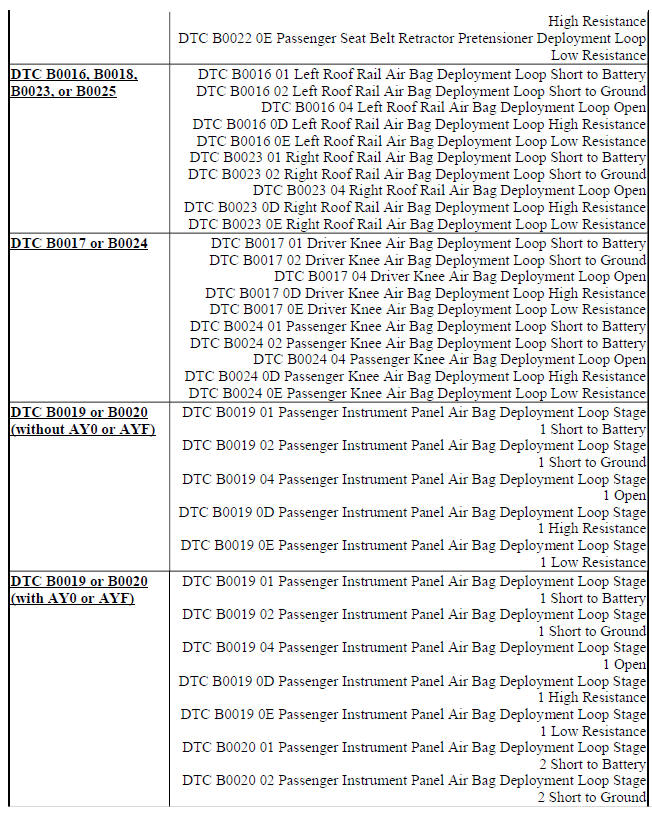

DTC B0019 OR B0020 (WITH AY0 OR AYF): Passenger instrument panel air bag deployment loop

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptors

DTC B0019 01

Passenger Instrument Panel Air Bag Deployment Loop Stage 1 Short to Battery

DTC B0019 02

Passenger Instrument Panel Air Bag Deployment Loop Stage 1 Short to Ground

DTC B0019 04

Passenger Instrument Panel Air Bag Deployment Loop Stage 1 Open

DTC B0019 0D

Passenger Instrument Panel Air Bag Deployment Loop Stage 1 High Resistance

DTC B0019 0E

Passenger Instrument Panel Air Bag Deployment Loop Stage 1 Low Resistance

DTC B0020 01

Passenger Instrument Panel Air Bag Deployment Loop Stage 2 Short to Battery

DTC B0020 02

Passenger Instrument Panel Air Bag Deployment Loop Stage 2 Short to Ground

DTC B0020 04

Passenger Instrument Panel Air Bag Deployment Loop Stage 2 Open

DTC B0020 0D

Passenger Instrument Panel Air Bag Deployment Loop Stage 2 High Resistance

DTC B0020 0E

Passenger Instrument Panel Air Bag Deployment Loop Stage 2 Low Resistance

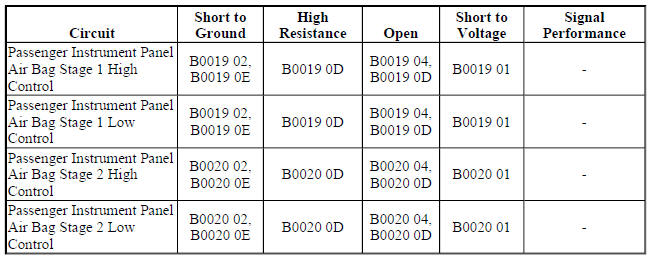

Diagnostic Fault Information

Circuit/System Description

During a side or frontal crash of sufficient force the inflatable restraint sensing and diagnostic module (SDM) will allow current to flow through the deployment loop in order to deploy an air bag or pretensioner. There are 2 shorting bars which will short the control circuits together when the connector is disconnected. This will help to prevent unwanted deployment of the air bag or pretensioner during servicing.

Conditions for Running the DTC

Ignition voltage is between 9-16 V.

Conditions for Setting the DTC

B0019 01, B0020 01

The air bag control circuit is shorted to voltage for 2 seconds.

B0019 02, B0020 02

The air bag control circuit is shorted to ground for 2 seconds.

B0019 04, B0020 04

The air bag control circuit is open for 2 seconds.

B0019 0D, B0020 0D

The air bag deployment loop resistance is greater than 4.2 ohms for 2 seconds.

B0019 0E, B0020 0E

The air bag deployment loop resistance is less than 1.4 ohms for 2 seconds.

Action Taken When the DTC Sets

- The inflatable restraint sensing and diagnostic module requests the instrument cluster to illuminate the AIR BAG indicator.

- The inflatable restraint sensing and diagnostic module will store a DTC, however if an event occurs the system will still attempt deployments.

Conditions for Clearing the DTC

- The condition for setting the DTC no longer exists.

- A history DTC will clear once 100 malfunction-free ignition cycles have occurred.

Diagnostic Aid

NOTE: The following diagnostic aids apply for both current and history DTCs.

An incorrectly installed connector position assurance (CPA) or incorrectly seated connector can cause a shorting bar to short both control circuits together. Check the connectors and CPAs if a DTC with symptom byte 02 or 0E is set, to ensure the shorting bars are not causing the circuits to be shorted together. Shorting bars are used in the locations listed below:

- Passenger instrument panel air bag

- Inline harness connectors

- Harness side of the inflatable restraint sensing and diagnostic module connector

Terminal fretting or incorrectly seated connectors can cause an open/high resistance condition. Check the circuit terminals for fretting or incorrectly seated connector if a DTC with symptom byte 04 or 0D is set.

Reference Information

Schematic Reference

SIR Schematics (Encore), SIR Schematics (Encore)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

Description and Operation

Supplemental Inflatable Restraint System Description and Operation

Electrical Information Reference

- Circuit Testing

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

- Connector Repairs

Scan Tool Reference

Control Module References for scan tool information

Special Tools

EL-38125-580 Terminal Release Tool Kit

Circuit/System Verification

NOTE:

- Refer to SIR Service Precautions.

- Inspect all terminals for damage or corrosion when disconnecting connectors. Damage or corrosion in the following requires repair or replacement of the affected component/connector.

- Passenger instrument panel air bag

- inflatable restraint sensing and diagnostic module

- Passenger instrument panel air bag wiring harness connector

- inflatable restraint sensing and diagnostic module wiring harness connector

- The connector and connector position assurance (CPA) may seat independent of each other. Both the connector and CPA should seat with an audible and/or tactile click. The CPA isolates the shorting-bars within the connector allowing the deployment circuit to operate properly.

- If the condition is intermittent or cannot be duplicated, disconnect the connectors and add dielectric grease / lubricant (Nyogel 760G or equivalent, meeting GM specification 9986087). This procedure will correct the high resistance condition due to terminal fretting corrosion.

- Verify the scan tool Deployment Loop Resistance parameters stay consistently between 2.1-4.0 ohms without any spikes or dropouts while moving the harness near each connector listed below:

- F105 Passenger Instrument Panel Air Bag

- Any inline harness connector

- K36 inflatable restraint sensing and diagnostic module

- If less than 2.1 ohms or greater than 4.0 ohms

Refer to Circuit/System Testing.

- If there are spikes or dropouts, perform the following

- Inspect each connector terminal and harness for damage or corrosion and repair as necessary

- Apply dielectric grease / lubricant (Nyogel 760G or equivalent, meeting GM specification 9986087) to each connector terminal

- Insure each connector and CPA is correctly seated.

- If between 2.1-4.0 ohms without any spikes or dropouts

- All OK.

Circuit/System Testing

- Ignition OFF, scan tool disconnected, disconnect the X206 inline harness connector for the F105 Passenger Instrument Panel Air Bag. It may take up to 2 min for all vehicle systems to power down.

- Test for greater than 25 ohms between the appropriate control circuit terminals listed below on the K36 Inflatable Restraint Sensing and Diagnostic Module side of the connector:

- F105 Passenger Instrument Panel Air Bag stage 1 X206 terminal 1 and 2

- F105 Passenger Instrument Panel Air Bag stage 2 X206 terminal 4 and 5

- If 25 ohms or less

- Disconnect the X1 harness connector at the K36 inflatable restraint sensing and diagnostic module.

NOTE: Some connectors may be equipped with shorting bars as a safety component to prevent accidental deployment. When testing on a connector with shorting bars, the shorting bars must be disabled to ensure accurate test results. Insert an appropriate pick from EL- 38125-580 and depress the shorting bars above the appropriate terminals. This will lift the shorting bar from the terminal and allow accurate test results. Take care not to damage the connector, shorting bar, or terminal when depressing the shorting bar.

- Test for infinite resistance between the two control circuits.

- If less than infinite resistance, repair the short between the two circuits.

- If infinite resistance, replace the K36 Inflatable Restraint Sensing and Diagnostic Module.

- If greater than 25 ohms

- Ignition ON.

- Test for less than 11 V between each control circuit terminal listed below on the instrument panel harness side of the connector and ground:

- X206 control circuit terminal 1

- X206 control circuit terminal 2

- X206 control circuit terminal 4

- X206 control circuit terminal 5

- If 11 V or greater

- Ignition OFF, disconnect the X1 harness connector at the K36 Inflatable Restraint Sensing and Diagnostic Module, ignition ON.

- Test for less than 1 V between each control circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V, replace the K36 Inflatable Restraint Sensing and Diagnostic Module.

- If less than 11 V

- Ignition OFF.

- Test for greater than 25 ohms between each control circuit terminal listed below on the instrument panel harness side of the connector and ground:

- X206 control circuit terminal 1

- X206 control circuit terminal 2

- X206 control circuit terminal 4

- X206 control circuit terminal 5

- If 25 ohms or less

- Disconnect the X1 harness connector at the K36 Inflatable Restraint Sensing and Diagnostic Module.

- Test for infinite resistance between the control circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance, replace the K36 Inflatable Restraint Sensing and Diagnostic Module.

- If greater than 25 ohms

- Install a 3 A fused jumper wire between the control circuit terminals listed below on the instrument panel harness side of the connector:

- F105 Passenger Instrument Panel Air Bag stage 1 X206 terminal 1 and 2

- F105 Passenger Instrument Panel Air Bag stage 2 X206 terminal 4 and 5

- Ignition ON.

- Verify DTC B0017 0E or B0024 0E is set.

- If DTC B0017 0E or B0024 0E is not set

- Ignition OFF, disconnect the X1 harness connector at the K36 Inflatable Restraint Sensing and Diagnostic Module.

- Test for less than 2 ohms in each control circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K36 Inflatable Restraint Sensing and Diagnostic Module.

- If DTC B0017 0E or B0024 0E is set

- Ignition OFF, connect the X206 inline harness connector and disconnect the appropriate X1 (DTC B0019) or X2 (DTC B0020) harness connector at the F105 Passenger instrument panel air bag, ignition ON.

- Test for less than 11 V between each control circuit terminals listed below and ground:

- F105 Passenger Instrument Panel Air Bag control circuit terminal 1 X1