Buick Encore: Engine Controls and Fuel - 1.4L - Description and operation

Camshaft actuator system description

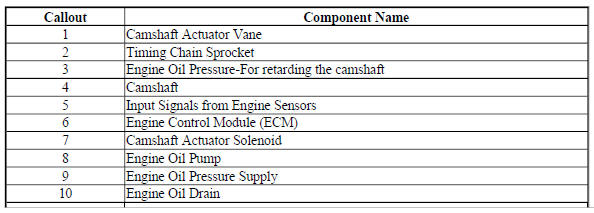

Camshaft Actuator System Overview

.gif)

Fig. 1: Identifying Camshaft Actuator System Components

The camshaft actuator system enables the engine control module (ECM) to change camshaft timing of all 4 camshafts while the engine is operating. The camshaft position (CMP) actuator assembly (15) varies the camshaft position in response to directional changes in oil pressure. The CMP actuator solenoid valve controls the oil pressure that is applied to advance or retard a camshaft. Modifying camshaft timing under changing engine demand provides better balance between the following performance concerns:

- Engine power output

- Fuel economy

- Tailpipe emissions

The CMP actuator solenoid valve (7) is controlled by the ECM. The crankshaft position (CKP) sensor and the CMP sensors are used to monitor changes in camshaft positions. The ECM uses the following information in order to calculate the desired camshaft positions:

- Engine coolant temperature

- Calculated engine oil temperature (EOT)

- Mass air flow (MAF)

- Throttle position (TP)

- Vehicle speed

- Volumetric efficiency

Operation

The CMP actuator assembly has an outer housing that is driven by an engine timing chain. Inside the assembly is a rotor with fixed vanes that is attached to the camshaft. Oil pressure that is applied to the fixed vanes will rotate a specific camshaft in relationship to the crankshaft. The movement of the intake camshafts will advance the intake valve timing. The movement of the exhaust camshafts will retard the exhaust valve timing. When oil pressure is applied to the return side of the vanes, the camshafts will return to 0 crankshaft degrees, or top dead center (TDC). The CMP actuator solenoid valve directs the oil flow that controls the camshaft movement. The ECM commands the CMP solenoid to move the solenoid plunger and spool valve until oil flows from the advance passage (11). Oil flowing thru the CMP actuator assembly from the CMP solenoid advance passage applies pressure to the advance side of the vanes in the CMP actuator assembly. When the camshaft position is retarded, the CMP actuator solenoid valve directs oil to flow into the CMP actuator assembly from the retard passage (3). The ECM can also command the CMP actuator solenoid valve to stop oil flow from both passages in order to hold the current camshaft position.

The ECM operates the CMP actuator solenoid valve by pulse width modulation (PWM) of the solenoid coil.

The higher the PWM duty cycle, the larger the change in camshaft timing. The CMP actuator assembly also contains a lock pin (14) that prevents movement between the outer housing and the rotor vane assembly. The lock pin is released by oil pressure before any movement in the CMP actuator assembly takes place. The ECM is continuously comparing CMP sensor inputs with CKP sensor input in order to monitor camshaft position and detect any system malfunctions. If a condition exists in either the intake or exhaust camshaft actuator system, the opposite bank, intake or exhaust, camshaft actuator will default to 0 crankshaft degrees.

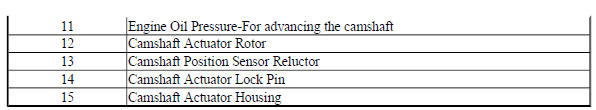

CMP Actuator System Operation

ELECTRONIC IGNITION SYSTEM DESCRIPTION

Electronic Ignition System Operation

The electronic ignition system produces and controls the high energy secondary spark. This spark ignites the compressed air/fuel mixture at precisely the correct time, providing optimal performance, fuel economy, and control of exhaust emissions. The engine control module (ECM) collects information from the crankshaft position sensor and the intake/exhaust camshaft position sensors to determine the sequence, dwell, and timing of the spark for each cylinder. The ECM transmits a frequency signal to the ignition coil module on the individual ignition control circuits to fire the spark plugs.

Crankshaft Position Sensor

The crankshaft position sensor is an externally magnetically biased digital output integrated circuit sensing device. The sensor provides a pulse for each magnetic pole of the encoder wheel on the crankshaft. The sensor produces an ON/OFF DC voltage of varying frequency, with 58 output pulses per crankshaft revolution. The frequency of the sensor output depends on the velocity of the crankshaft. The ECM uses sensor signal pulse to determine crankshaft speed and position to calculate the best timing for ignition and fuel injection. The ECM also uses the crankshaft position sensor information to control camshaft phasing and to detect cylinder misfire.

The ECM also has a dedicated replicated crankshaft position sensor signal output circuit that may be used as an input signal to other modules for monitoring engine RPM.

The crankshaft position sensor is connected to the engine control module by the circuits listed below:

- A 5 V reference circuit

- A low reference circuit

- A signal circuit

Crankshaft Encoder Wheel

The crankshaft encoder wheel is part of the crankshaft. The encoder wheel consists of 58 tooth and a reference gap. Each tooth on the encoder wheel is spaced 6º apart with a 12º space for the reference gap. The pulse from the reference gap is known as the sync pulse. The sync pulse is used to synchronize the ignition coil module firing sequence with the crankshaft position while the other tooth provides cylinder location during a revolution.

Camshaft Position Sensors

The intake and exhaust camshaft position sensors are each triggered by a notched reluctor wheel built onto the camshaft sprockets. The four signal pulses occur every camshaft revolution. Each notch is a different size which is used to identify the compression stroke of each cylinder and to enable sequential fuel injection. The camshaft position sensors are connected to the ECM by the circuits listed below:

- A 5 V reference circuit

- A low reference circuit

- A signal circuit

Knock Sensor

The knock sensor system enables the control module to control the ignition timing for the best possible performance while protecting the engine from potentially damaging levels of detonation, also known as spark knock. The knock sensor system uses 1 or 2 flat response 2-wire sensors. The sensor uses piezo-electric crystal technology that produces an AC voltage signal of varying amplitude and frequency based on the engine vibration or noise level. The amplitude and frequency depend upon the level of knock that the knock sensor detects. The control module receives the knock sensor signal through the signal circuit. The knock sensor ground is supplied by the control module through the low reference circuit.

The control module learns a minimum noise level, or background noise, at idle from the knock sensor and uses calibrated values for the rest of the RPM range. The control module uses the minimum noise level to calculate a noise channel. A normal knock sensor signal will ride within the noise channel. As engine speed and load change, the noise channel upper and lower parameters will change to accommodate the normal knock sensor signal, keeping the signal within the channel. In order to determine which cylinders are knocking, the control module only uses knock sensor signal information when each cylinder is near top dead center (TDC) of the firing stroke. If knock is present, the signal will range outside of the noise channel.

If the control module has determined that knock is present, it will retard the ignition timing to attempt to eliminate the knock. The control module will always try to work back to a zero compensation level, or no spark retard. An abnormal knock sensor signal will stay outside of the noise channel or will not be present. Knock sensor diagnostics are calibrated to detect faults with the knock sensor circuitry inside the control module, the knock sensor wiring, or the knock sensor voltage output. Some diagnostics are also calibrated to detect constant noise from an outside influence such as a loose/damaged component or excessive engine mechanical noise.

Ignition Coil Module

The ignition coil module integrates the 4 coils and the ignition control module within a single sealed component.

The ignition coil module has the following circuits:

- An ignition voltage circuit

- A ground

- A low reference circuit

- 4 ignition coil control circuits

The ECM controls the individual coils by transmitting timing pulses on the ignition coil control circuit to each ignition coil to enable a spark event.

The spark plugs are connected to each coil by a short boot. The boot contains a spring that conducts the spark energy from the coil to the spark plug. The spark plug electrode is coated with platinum for long wear and higher efficiency.

Engine Control Module [ECM]

The ECM controls all ignition system functions and constantly adjusts the spark timing. The ECM monitors information from various sensor inputs that include the following:

- The crankshaft position sensor

- The accelerator pedal position (APP)

- The manifold absolute pressure (MAP) sensor

- The intake air temperature (IAT) sensor

- The vehicle speed sensor (VSS)

- The engine knock sensor

- The engine coolant temperature (ECT) sensor

- The mass airflow (MAF) sensor

- The camshaft position sensors

Engine control module description

The Engine Control Module (ECM) interacts with many emission related components and systems, and monitors emission related components and systems for deterioration. OBD II diagnostics monitor the system performance and a diagnostic trouble code (DTC) sets if the system performance degrades. The ECM is part of a network and communicates with various other vehicle control modules.

Malfunction indicator lamp (MIL) operation and DTC storage are dictated by the DTC type. A DTC is ranked as a Type A or Type B if the DTC is emissions related. Type C is a non-emissions related DTC.

The ECM is the control center of the engine controls system. Review the components and wiring diagrams in order to determine which systems are controlled by the ECM.

The ECM constantly monitors the information from various sensors and other inputs, and controls the systems that affect engine performance and emissions. The ECM also performs diagnostic tests on various parts of the system and can turn on the MIL when it recognizes an operational problem that affects emissions. When the ECM detects a malfunction, the ECM stores a DTC. The condition area is identified by the particular DTC that is set. This aids the technician in making repairs.

ECM Function

The ECM can supply 5 V or 12 V to various sensors or switches. This is done through pull-up resistors to regulated power supplies within the ECM. In some cases, even an ordinary shop voltmeter will not give an accurate reading due to low input resistance. Therefore, a digital multimeter (DMM) with at least 10 megaohms input impedance is required in order to ensure accurate voltage readings.

The ECM controls the output circuits by controlling the ground or the power feed circuit through transistors or a device called an output driver module.

EEPROM

The electronically erasable programmable read only memory (EEPROM) is an integral part of the ECM. The EEPROM contains program and calibration information that the ECM needs in order to control engine operation.

Special equipment, as well as the correct program and calibration for the vehicle, are required in order to reprogram the ECM.

Data Link Connector (DLC)

The data link connector (DLC) provides serial data communication for ECM diagnosis. This connector allows the technician to use a scan tool in order to monitor various serial data parameters, and display DTC information. The DLC is located inside the driver's compartment, underneath the instrument panel.

Malfunction Indicator Lamp (MIL)

The malfunction indicator lamp (MIL) is inside the instrument panel cluster (IPC). The MIL is controlled by the ECM and illuminates when the ECM detects a condition that affects vehicle emissions.

ECM Service Precautions

The ECM, by design, can withstand normal current draws that are associated with vehicle operations. However, care must be used in order to avoid overloading any of these circuits. When testing for opens or shorts, do not ground or apply voltage to any of the ECM circuits unless the diagnostic procedure instructs you to do so.

These circuits should only be tested with a DMM unless the diagnostic procedure instructs otherwise.

Emissions Diagnosis For State I/M Programs

This OBD II equipped vehicle is designed to diagnose any conditions that could lead to excessive levels of the following emissions:

- Hydrocarbons (HC)

- Carbon monoxide (CO)

- Oxides of nitrogen (NOx)

- Evaporative emission (EVAP) system losses

Should this vehicle's on-board diagnostic system (ECM) detect a condition that could result in excessive emissions, the ECM turns ON the MIL and stores a DTC that is associated with the condition.

Aftermarket (Add-On) Electrical And Vacuum Equipment

CAUTION: Do not attach add-on vacuum operated equipment to this vehicle. The use of add-on vacuum equipment may result in damage to vehicle components or systems.

CAUTION: Connect any add-on electrically operated equipment to the vehicle's electrical system at the 12 V battery (power and ground) in order to prevent damage to the vehicle.

Aftermarket, add-on, electrical and vacuum equipment is defined as any equipment installed on a vehicle after leaving the factory that connects to the vehicle's electrical or vacuum systems. No allowances have been made in the vehicle design for this type of equipment.

Add-on electrical equipment, even when installed to these strict guidelines, may still cause the powertrain system to malfunction. This may also include equipment not connected to the vehicle electrical system, such as portable telephones and radios. Therefore, the first step in diagnosing any powertrain condition is to eliminate all of the aftermarket electrical equipment from the vehicle. After this is done, if the problem still exists, the problem may be diagnosed in the normal manner.

Electrostatic Discharge (ESD) Damage

NOTE: In order to prevent possible electrostatic discharge damage to the ECM, DO NOT touch the connector pins on the ECM.

The electronic components that are used in the control systems are often designed to carry very low voltage.

These electronic components are susceptible to damage caused by electrostatic discharge. Less than 100 V of static electricity can cause damage to some electronic components. By comparison, it takes as much as 4,000 V for a person to even feel a static discharge.

There are several ways for a person to become statically charged. The most common methods of charging are by friction and by induction. An example of charging by friction is a person sliding across a car seat.

Charging by induction occurs when a person with well insulated shoes stands near a highly charged object and momentarily touches ground. Charges of the same polarity are drained off leaving the person highly charged with the opposite polarity. Static charges can cause damage, therefore, it is important to use care when handling and testing electronic components.

Emissions Control Information Label

The underhood Vehicle Emissions Control Information Label contains important emission specifications. This identifies the year, the displacement of the engine in liters, and the class of the vehicle.

This label is located in the engine compartment of every General Motors vehicle. If the label has been removed, it can be ordered from GM service parts operations (GMSPO).

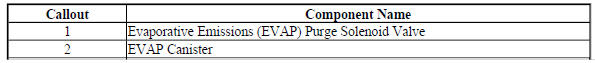

EVAPORATIVE EMISSION CONTROL SYSTEM DESCRIPTION

Typical Evaporative Emission (EVAP) System Hose Routing Diagram

.gif)

Fig. 2: View Of Evaporative Emission (EVAP) System Hose Routing Diagram

EVAP System Operation

The evaporative emission (EVAP) control system limits fuel vapors from escaping into the atmosphere. Fuel tank vapors are allowed to move from the fuel tank, due to pressure in the tank, through the EVAP vapor tube, into the EVAP canister. Carbon in the canister absorbs and stores the fuel vapors. Excess pressure is vented through the vent hose and EVAP vent solenoid valve to the atmosphere. The EVAP canister stores the fuel vapors until the engine is able to use them. At an appropriate time, the engine control module (ECM) will command the EVAP purge solenoid valve ON, allowing engine vacuum to be applied to the EVAP canister.

With the normally open EVAP vent solenoid valve OFF, fresh air is drawn through the vent solenoid valve and the vent hose to the EVAP canister. Fresh air is drawn through the canister, pulling fuel vapors from the carbon.

The air/fuel vapor mixture continues through the EVAP purge tube and EVAP purge solenoid valve into the intake manifold to be consumed during normal combustion. The ECM uses several tests to determine if the EVAP system is leaking or restricted.

Purge Solenoid Valve Leak Test

If the EVAP purge solenoid valve does not seal properly fuel vapors could enter the engine at an undesired time, causing driveability concerns. The ECM tests for this by commanding the EVAP purge solenoid valve OFF and the vent solenoid valve ON which seals the system. With the engine running, the ECM then monitors the fuel tank pressure (FTP) sensor for an increase in vacuum. The ECM will log a fault if a vacuum develops in the tank under these test conditions.

Large Leak Test

This diagnostic creates a vacuum condition in the EVAP system. When the enabling criteria has been met, the ECM commands the normally open EVAP vent solenoid valve closed and the EVAP purge solenoid valve open, creating a vacuum in the EVAP system. The ECM then monitors the FTP sensor voltage to verify that the system is able to reach a predetermined level of vacuum within a set amount of time. Failure to achieve the expected level of vacuum indicates the presence of a large leak in the EVAP system or a restriction in the purge path. The ECM will log a fault if it detects a weaker than expected vacuum level under these test conditions.

Canister Vent Restriction Test

If the EVAP vent system is restricted, fuel vapors will not be properly purged from the EVAP canister. The ECM tests this by commanding the EVAP purge solenoid valve ON while commanding the EVAP vent solenoid valve OFF, and then monitoring the FTP sensor for an increase in vacuum. If the vacuum increases more than the expected amount, in a set amount of time, a fault will be logged by the ECM.

Small Leak Test

The engine off natural vacuum diagnostic is the small-leak detection diagnostic for the EVAP system. The engine off natural vacuum diagnostic monitors the EVAP system pressure with the ignition OFF. Because of this, it may be normal for the ECM to remain active for up to 40 min after the ignition is turned OFF. This is important to remember when performing a parasitic draw test on vehicles equipped with engine off natural vacuum.

When the vehicle is driven, the temperature rises in the tank due to heat transfer from the exhaust system. After the vehicle is parked, the temperature in the tank continues to rise for a period of time, then starts to drop. The engine off natural vacuum diagnostic relies on this temperature change, and the corresponding pressure change in a sealed system, to determine if an EVAP system leak is present.

The engine off natural vacuum diagnostic is designed to detect leaks as small as 0.51 mm (0.020 in).

EVAP System Components

The EVAP system consists of the following components

EVAP Purge Solenoid Valve

The EVAP purge solenoid valve controls the flow of vapors from the EVAP system to the intake manifold. The purge solenoid valve opens when commanded ON by the ECM. This normally closed valve is pulse width modulated (PWM) by the ECM to precisely control the flow of fuel vapor to the engine. The valve will also be opened during some portions of the EVAP testing when the engine is running, allowing engine vacuum to enter the EVAP system.

Purge Tube Check Valve

Turbocharged vehicles have a check valve in the purge tube between the EVAP purge solenoid valve and the EVAP canister to prevent pressurization of the EVAP system under boost conditions. Note that the presence of this one-way check valve prevents pressure testing the EVAP system for leaks at the EVAP canister purge tube connector.

EVAP Canister

The canister is filled with carbon pellets used to absorb and store fuel vapors. Fuel vapor is stored in the canister until the ECM determines that the vapor can be consumed in the normal combustion process.

Vapor Recirculation Tube

A vapor path between the fuel fill pipe and the vapor tube to the carbon canister is necessary for Vehicle Onboard Diagnostics to fully diagnose the EVAP system. It also accommodates service diagnostic procedures by allowing the entire EVAP system to be diagnosed from either end of the system.

Fuel Tank Pressure Sensor

The FTP sensor measures the difference between the pressure or vacuum in the fuel tank and outside air pressure. The ECM provides a 5 V reference and a ground to the FTP sensor. Depending on the vehicle, the sensor can be located in the vapor space on top of the fuel tank, in the vapor tube between the canister and the tank, or on the EVAP canister. The FTP sensor provides a signal voltage back to the ECM that can vary between 0.1-4.9 V. A high FTP sensor voltage indicates a low fuel tank pressure or vacuum. A low FTP sensor voltage indicates a high fuel tank pressure.

Fuel Fill Pipe Check Valve

The check valve on the fuel fill pipe is there to prevent spit-back during refueling.

EVAP Vent Solenoid Valve

The EVAP vent solenoid valve controls fresh airflow into the EVAP canister. The valve is normally open. The canister vent solenoid valve is closed only during EVAP system tests performed by the ECM.

Fuel Fill Cap

The fuel fill cap is equipped with a seal and a vacuum relief valve.

Capless Fuel Fill

Some vehicles may have a capless fuel fill design behind a locking fuel door. There is no fuel fill cap to remove. One just fully inserts the fuel nozzle into the fill neck, making sure it latches before refueling. Flapper valves close to seal this interface once the fill nozzle is removed.

Fuel system description (LUJ)

Fuel System Overview

The engine control module (ECM) enables the fuel pump relay when the ignition switch is turned ON. The ECM will disable the fuel pump relay within 2 seconds unless the control module detects ignition reference pulses. The ECM continues to enable the fuel pump relay as long as ignition reference pulses are detected. The ECM disables the fuel pump relay within 2 seconds if ignition reference pulses cease to be detected and the ignition remains ON.

An electric turbine style fuel pump attaches to the fuel tank fuel pump module inside the fuel tank. The fuel pump supplies high pressure fuel through the fuel feed pipe to the fuel injection system. The fuel pump provides fuel at a higher rate of flow than is needed by the fuel injection system. The fuel pump also supplies fuel to a jet pump located in the fuel tank fuel pump module. The function of the jet pump is to fill the fuel tank fuel pump module reservoir. The fuel pressure regulator, a part of the fuel rail, maintains the correct fuel pressure to the fuel injection system. The fuel return pipe returns unused fuel to the fuel tank. The fuel tank fuel pump module contains a reverse flow check valve. The check valve and the fuel pressure regulator maintain fuel pressure in the fuel feed pipe and the fuel rail in order to prevent long cranking times.

Fuel Tank

The fuel tank stores the fuel supply. The fuel tank is located in the rear of the vehicle. The fuel tank is held in place by 2 metal straps that are attached to the underbody. The fuel tank is molded from high-density polyethylene.

The fuel tank on all wheel drive models is a saddle configuration in order to provide space for a driveshaft through the center area of the fuel tank. Because of the saddle shape of the tank, two fuel pump modules are required.

Fuel Filler Cap

The fuel fill pipe has a tethered fuel filler cap. A torque-limiting device prevents the cap from being overtightened. To install the cap, turn the cap clockwise until the cap clicks audibly. This indicates that the cap is correctly torqued and fully seated.

Fuel Tank Fuel Pump Module

The fuel tank fuel pump module consists of the following components:

- The fuel level sensor

- The fuel pump

- The fuel strainer

- The primary jet pump

- The secondary jet pump - AWD models

Fuel Sender Assembly - AWD Models

The fuel sender assembly consists of the following components:

- The fuel level sensor

- The fuel pick-up

Fuel Level Sensor

The fuel level sensor consists of a float, a wire float arm, and a ceramic resistor card. The position of the float arm indicates the fuel level. The fuel level sensor contains a variable resistor which changes resistance in correspondence with the position of the float arm. The ECM sends the fuel level signal via a High Speed CANBus signal to the body control module (BCM). The BCM then sends the information via a Low Speed CANBus signal to the instrument cluster to display the fuel level. When the fuel level falls below 11% the instrument cluster illuminates the low fuel level indicator. The ECM also monitors the fuel level input for various diagnostics.

Fuel Pump

The fuel pump is mounted in the fuel tank fuel pump module reservoir. The fuel pump is an electric highpressure pump. Fuel is pumped to the fuel injection system at specified rates of flow and pressure. Excess fuel from the fuel injection system returns to the fuel tank through the fuel return pipe. The fuel pump delivers a constant flow of fuel to the engine even during low fuel conditions and aggressive vehicle maneuvers. The ECM controls the electric fuel pump operation through a fuel pump relay. The fuel pump flex pipe acts to dampen the fuel pulses and noise generated by the fuel pump.

Fuel Strainer

The fuel strainer is attached to the lower end of the fuel tank fuel pump module. The fuel strainer is made of woven plastic. The functions of the fuel strainer are to filter contaminants and to wick away fuel. Normally, the fuel strainer does not require maintenance. Fuel stoppage at this point indicates that the fuel tank contains an abnormal amount of sediment or contamination.

Primary and Secondary Jet Pumps

The primary jet pump is located in the fuel tank fuel pump module. Fuel pump flow loss, caused by vapor expulsion in the pump inlet chamber, is diverted to the primary jet pump and the secondary jet pump through a restrictive orifice located on the pump cover. The primary jet pump fills the reservoir of the fuel tank fuel pump module.

The secondary jet pump creates a venturi action which causes the fuel to be drawn from the secondary side of the fuel tank, through the transfer pipe, to the primary side of the fuel tank.

Nylon Fuel Pipes

WARNING: Refer to Fuel and Evaporative Emission Pipe Warning .

Nylon pipes are constructed to withstand maximum fuel system pressure, exposure to fuel additives, and changes in temperature.

Heat resistant rubber hose or corrugated plastic conduit protect the sections of the pipes that are exposed to chafing, high temperature, or vibration.

Nylon fuel pipes are somewhat flexible and can be shaped around gradual turns under the vehicle. However, if nylon fuel pipes are forced into sharp bends, the pipes may kink and restrict the flow of fuel. Also, once exposed to fuel, nylon pipes may become stiffer and are more likely to kink if bent too far. Exercise special care when working on a vehicle with nylon fuel pipes.

Quick-Connect Fittings

Nylon fuel pipes are somewhat flexible and can be shaped around gradual turns under the vehicle. However, if nylon fuel pipes are forced into sharp bends, the pipes may kink and restrict the flow of fuel. Also, once exposed to fuel, nylon pipes may become stiffer and are more likely to kink if bent too far. Exercise special care when working on a vehicle with nylon fuel pipes.

Fuel Rail Assembly

The fuel rail assembly is attached to the engine intake manifold. The fuel rail assembly performs the following functions:

- Positions the injectors in the intake manifold

- Distributes fuel evenly to the injectors

Fuel Injectors

The fuel injector assembly is a solenoid device controlled by the ECM that meters pressurized fuel to a single engine cylinder. The ECM energizes the high-impedance, 12 ohms, injector solenoid to open a ball valve, normally closed. This allows fuel to flow into the top of the injector, past the ball valve, and through a director plate at the injector outlet. The director plate has machined holes that control the flow of fuel, generating a spray of finely atomized fuel at the injector tip. Fuel from the injector tip is directed at the intake valve, causing the fuel to become further atomized and vaporized before entering the combustion chamber. This fine atomization improves fuel economy and emissions.

Fuel Pressure Regulator Assembly

The fuel pressure regulator is a diaphragm relief valve. The diaphragm has fuel pressure on one side and regulator spring pressure on the other side. Fuel pressure is controlled by a pressure balance across the regulator. The fuel system pressure is constant. A software bias compensates the injector on-time based on the signal from the MAP sensor.

Fuel Metering Modes of Operation

The ECM monitors voltages from several sensors in order to determine how much fuel to feed to the engine.

The ECM controls the amount of fuel delivered to the engine by changing the fuel injector pulse width. The fuel is delivered under one of several modes.

Starting Mode

When the ignition is first turned ON, the ECM energizes the fuel pump relay for 2 seconds. This allows the fuel pump to build pressure in the fuel system. The ECM calculates the air/fuel ratio based on inputs from the engine coolant temperature (ECT), the barometric pressure (BARO), mass air flow (MAF), and throttle position sensors. The system stays in starting mode until the engine speed reaches a predetermined RPM.

Clear Flood Mode

If the engine is flooded with fuel during starting and will not start, the clear flood mode can be manually enabled. To enable Clear Flood Mode, press the accelerator to wide open throttle (WOT). The ECM will completely turn OFF the fuel injectors and will maintain this mode as long as the ECM detects a WOT condition with engine speed below a predetermined value.

Run Mode

The run mode has 2 conditions called Open Loop and Closed Loop. When the engine is first started and the engine speed is above a predetermined RPM, the system begins Open Loop operation. The ECM ignores the signal from the heated oxygen sensor (HO2S). The ECM calculates the air/fuel ratio based on inputs from the engine coolant temperature (ECT), manifold absolute pressure (MAP), mass air flow (MAF), and throttle position sensors. The system stays in Open Loop until meeting the following conditions:

- The HO2S has varying voltage output, showing that the HO2S is hot enough to operate properly.

- The ECT sensor is above a specified temperature.

- A specific amount of time has elapsed after starting the engine.

Specific values for the above conditions exist for each different engine, and are stored in the electrically erasable programmable read-only memory (EEPROM). The system begins Closed Loop operation after reaching these values. In Closed Loop, the ECM calculates the air/fuel ratio, injector ON time, based upon the signal from various sensors, but mainly from the HO2S. This allows the air/fuel ratio to stay very close to 14.7:1.

Acceleration Mode

When the driver pushes on the accelerator pedal, air flow into the cylinders increases rapidly. To prevent possible hesitation, the ECM increases the pulse width to the injectors to provide extra fuel during acceleration.

This is also known as power enrichment. The ECM determines the amount of fuel required based upon throttle position, engine coolant temperature (ECT), manifold absolute pressure (MAP), mass air flow (MAF), and engine speed.

Deceleration Mode

When the driver releases the accelerator pedal, air flow into the engine is reduced. The ECM monitors the corresponding changes in throttle position, mass air flow (MAF), and manifold absolute pressure (MAP). The ECM shuts OFF fuel completely if the deceleration is very rapid, or for long periods, such as long, closedthrottle coast-down. The fuel shuts OFF in order to prevent damage to the catalytic converters

Battery Voltage Correction Mode

When the battery voltage is low, the ECM compensates for the weak spark delivered by the ignition system in the following ways:

- Increasing the amount of fuel delivered

- Increasing the idle RPM

- Increasing the ignition dwell time

Fuel Cutoff Mode

The ECM cuts OFF fuel from the fuel injectors when the following conditions are met in order to protect the powertrain from damage and improve driveability:

- The ignition is OFF. This prevents engine run-on.

- The ignition is ON but there is no ignition reference signal. This prevents flooding or backfiring.

- The engine speed is too high, above red line.

- The vehicle speed is too high, above rated tire speed.

- During an extended, high speed, closed throttle coast down-This reduces emissions and increases engine braking.

- During extended deceleration, in order to prevent damage to the catalytic converters

Fuel Trim

The ECM controls the air/fuel metering system in order to provide the best possible combination of driveability, fuel economy, and emission control. The ECM monitors the heated oxygen sensor (HO2S) signal voltage while in Closed Loop and regulates the fuel delivery by adjusting the pulse width of the injectors based on this signal.

The ideal fuel trim values are around 0 percent for both short and long term fuel trim. A positive fuel trim value indicates the ECM is adding fuel in order to compensate for a lean condition by increasing the pulse width. A negative fuel trim value indicates that the ECM is reducing the amount of fuel in order to compensate for a rich condition by decreasing the pulse width. A change made to the fuel delivery changes the long and short term fuel trim values. The short term fuel trim values change rapidly in response to the HO2S signal voltage. These changes fine tune the engine fueling. The long term fuel trim makes coarse adjustments to fueling in order to recenter and restore control to short term fuel trim. A scan tool can be used to monitor the short and long term fuel trim values. The long term fuel trim diagnostic is based on an average of several of the long term speed load learn cells. The ECM selects the cells based on the engine speed and engine load. If the ECM detects an excessively lean or rich condition, the ECM will set a fuel trim diagnostic trouble code (DTC).

Fuel system description (LUV)

Fuel System Overview

The fuel system is an electronic returnless on-demand design. A returnless fuel system reduces the internal temperature of the fuel tank by not returning hot fuel from the engine to the fuel tank. Reducing the internal temperature of the fuel tank results in lower evaporative emissions.

The fuel tank stores the fuel supply. An electric turbine style fuel pump attaches to the fuel tank fuel pump module inside the fuel tank. The fuel pump supplies fuel through the fuel feed pipe to the fuel injection system.

The fuel tank fuel pump module contains a reverse flow check valve. The check valve maintains fuel pressure in the fuel feed pipe and the fuel rail in order to prevent long cranking times.

Electronic Returnless Fuel System

The electronic returnless fuel system is a microprocessor controlled fuel delivery system which transports fuel from the tank to the fuel rail. It functions as an electronic replacement for a traditional, mechanical fuel pressure regulator. A pressure relief regulator valve within the fuel tank provides an added measure of over pressure protection. Desired fuel pressure is commanded by the engine control module (ECM), and transmitted to the chassis control module via a GMLAN serial data message. A liquid fuel pressure sensor provides the feedback the chassis control module requires for Closed Loop fuel pressure control.

Chassis Control Module

The chassis control module is a serviceable GMLAN module. The chassis control module receives the desired fuel pressure message from the engine control module (ECM) and controls the fuel pump located within the fuel tank to achieve the desired fuel pressure. The chassis control module sends a 25 kHz PWM signal to the fuel pump, and pump speed is changed by varying the duty cycle of this signal. Maximum current supplied to the fuel pump is 15 A. A liquid fuel pressure sensor provides fuel pressure feedback to the chassis control module.

Fuel Pressure Sensor

The fuel pressure sensor is a serviceable 5 V, 3-pin device. It is located on the fuel feed line forward of the fuel tank, and receives power and ground from the chassis control module through a vehicle wiring harness. The sensor provides a fuel pressure signal to the chassis control module, which is used to provide Closed Loop fuel pressure control.

Fuel Tank

The fuel tank stores the fuel supply. The fuel tank is located in the rear of the vehicle. The fuel tank is held in place by 2 metal straps that are attached to the underbody. The fuel tank is molded from high-density polyethylene.

Fuel Filler Cap

The fuel fill pipe has a tethered fuel filler cap. A torque-limiting device prevents the cap from being overtightened. To install the cap, turn the cap clockwise until the cap clicks audibly. This indicates that the cap is correctly torqued and fully seated.

Fuel Tank Fuel Pump Module

The fuel tank fuel pump module consists of the following components:

- The fuel level sensor

- The fuel pump

- The fuel strainer

- The pressure relief regulator valve

- The jet pump

Fuel Level Sensor

The fuel level sensor consists of a float, a wire float arm, and a ceramic resistor card. The position of the float arm indicates the fuel level. The fuel level sensor contains a variable resistor which changes resistance in correspondence with the position of the float arm. The ECM sends the fuel level signal via a High Speed CANBus signal to the body control module (BCM). The BCM then sends the information via a Low Speed CANBus signal to the instrument cluster to display the fuel level. When the fuel level falls below 11% the instrument cluster illuminates the low fuel level indicator. The ECM also monitors the fuel level input for various diagnostics.

Fuel Pump

The fuel pump is mounted in the fuel tank fuel pump module reservoir. The fuel pump is an electric pump. Fuel is pumped to the fuel injection system at a pressure that is based on feedback from the fuel pressure sensor. The fuel pump delivers a constant flow of fuel even during low fuel conditions and aggressive vehicle maneuvers.

The fuel pump flex pipe acts to dampen the fuel pulses and noise generated by the fuel pump.

Fuel Strainer

The fuel strainer is attached to the lower end of the fuel tank fuel pump module. The fuel strainer is made of woven plastic. The functions of the fuel strainer are to filter contaminants and to wick away fuel. Normally, the fuel strainer does not require maintenance. Fuel stoppage at this point indicates that the fuel tank contains an abnormal amount of sediment or contamination.

Jet Pump

The jet pump is located in the fuel tank fuel pump module. Fuel pump flow loss, caused by vapor expulsion in the pump inlet chamber, is diverted to the jet pump through a restrictive orifice located on the pump cover. The jet pump fills the reservoir of the fuel tank fuel pump module.

Pressure Relief Regulator Valve

The pressure relief regulator valve replaces the typical fuel pressure regulator used on a mechanical returnless fuel system. The pressure relief regulator valve is closed during normal vehicle operation. The pressure relief regulator valve is used to vent pressure during hot soaks and also functions as a fuel pressure regulator in the event of the chassis control module defaulting to 100% pulse width modulation (PWM) of the fuel pump. Due to variation in the fuel system pressures, the opening pressure for the pressure relief regulator valve is set higher than the pressure that is used on a mechanical returnless fuel system pressure regulator.

Nylon Fuel Pipes

WARNING: Refer to Fuel and Evaporative Emission Pipe Warning .

Nylon pipes are constructed to withstand maximum fuel system pressure, exposure to fuel additives, and changes in temperature.

Heat resistant rubber hose or corrugated plastic conduit protect the sections of the pipes that are exposed to chafing, high temperature, or vibration.

Nylon fuel pipes are somewhat flexible and can be shaped around gradual turns under the vehicle. However, if nylon fuel pipes are forced into sharp bends, the pipes may kink and restrict the flow of fuel. Also, once exposed to fuel, nylon pipes may become stiffer and are more likely to kink if bent too far. Exercise special care when working on a vehicle with nylon fuel pipes.

Quick-Connect Fittings

Nylon fuel pipes are somewhat flexible and can be shaped around gradual turns under the vehicle. However, if nylon fuel pipes are forced into sharp bends, the pipes may kink and restrict the flow of fuel. Also, once exposed to fuel, nylon pipes may become stiffer and are more likely to kink if bent too far. Exercise special care when working on a vehicle with nylon fuel pipes.

Fuel Rail Assembly

The fuel rail assembly is attached to the engine intake manifold. The fuel rail assembly performs the following functions:

- Positions the injectors in the intake manifold

- Distributes fuel evenly to the injectors

Fuel Injectors

The fuel injector assembly is a solenoid device controlled by the ECM that meters pressurized fuel to a single engine cylinder. The ECM energizes the high-impedance, 12 ohms, injector solenoid to open a ball valve, normally closed. This allows fuel to flow into the top of the injector, past the ball valve, and through a director plate at the injector outlet. The director plate has machined holes that control the flow of fuel, generating a spray of finely atomized fuel at the injector tip. Fuel from the injector tip is directed at the intake valve, causing the fuel to become further atomized and vaporized before entering the combustion chamber. This fine atomization improves fuel economy and emissions.

Fuel Metering Modes of Operation

The ECM monitors voltages from several sensors in order to determine how much fuel to feed to the engine.

The ECM controls the amount of fuel delivered to the engine by changing the fuel injector pulse width. The fuel is delivered under one of several modes.

Starting Mode

The ECM supplies voltage to the chassis control module when the ECM detects that the ignition is ON. The voltage from the ECM to the chassis control module remains active for 2 s, unless the engine is in Crank or Run. While this voltage is being received, the chassis control module closes the ground switch of the fuel tank fuel pump module and also supplies a varying voltage to the fuel tank fuel pump module in order to maintain the desired fuel line pressure. The ECM calculates the air/fuel ratio based on inputs from the engine coolant temperature (ECT), manifold absolute pressure (MAP), mass air flow (MAF), and throttle position sensors. The system stays in starting mode until the engine speed reaches a predetermined RPM.

Clear Flood Mode

If the engine is flooded with fuel during starting and will not start, the clear flood mode can be manually enabled. To enable Clear Flood Mode, press the accelerator to wide open throttle (WOT). The ECM will completely turn OFF the fuel injectors and will maintain this mode as long as the ECM detects a WOT condition with engine speed below a predetermined value.

Run Mode

The run mode has 2 conditions called Open Loop and Closed Loop. When the engine is first started and the engine speed is above a predetermined RPM, the system begins Open Loop operation. The ECM ignores the signal from the heated oxygen sensor (HO2S). The ECM calculates the air/fuel ratio based on inputs from the engine coolant temperature (ECT), manifold absolute pressure (MAP), mass air flow (MAF), and throttle position sensors. The system stays in Open Loop until meeting the following conditions:

- The HO2S has varying voltage output, showing that the HO2S is hot enough to operate properly.

- The ECT sensor is above a specified temperature.

- A specific amount of time has elapsed after starting the engine.

Specific values for the above conditions exist for each different engine, and are stored in the electrically erasable programmable read-only memory (EEPROM). The system begins Closed Loop operation after reaching these values. In Closed Loop, the ECM calculates the air/fuel ratio, injector ON time, based upon the signal from various sensors, but mainly from the HO2S. This allows the air/fuel ratio to stay very close to 14.7:1.

Acceleration Mode

When the driver pushes on the accelerator pedal, air flow into the cylinders increases rapidly. To prevent possible hesitation, the ECM increases the pulse width to the injectors to provide extra fuel during acceleration.

This is also known as power enrichment. The ECM determines the amount of fuel required based upon throttle position, engine coolant temperature (ECT), manifold absolute pressure (MAP), mass air flow (MAF), and engine speed.

Deceleration Mode

When the driver releases the accelerator pedal, air flow into the engine is reduced. The ECM monitors the corresponding changes in throttle position, mass air flow (MAF), and manifold absolute pressure (MAP). The ECM shuts OFF fuel completely if the deceleration is very rapid, or for long periods, such as long, closedthrottle coast-down. The fuel shuts OFF in order to prevent damage to the catalytic converters.

Battery Voltage Correction Mode

When the battery voltage is low, the ECM compensates for the weak spark delivered by the ignition system in the following ways:

- Increasing the amount of fuel delivered

- Increasing the idle RPM

- Increasing the ignition dwell time

Fuel Cutoff Mode

The ECM cuts OFF fuel from the fuel injectors when the following conditions are met in order to protect the powertrain from damage and improve driveability:

- The ignition is OFF. This prevents engine run-on.

- The ignition is ON but there is no ignition reference signal. This prevents flooding or backfiring.

- The engine speed is too high, above red line.

- The vehicle speed is too high, above rated tire speed.

- During an extended, high speed, closed throttle coast down-This reduces emissions and increases engine braking.

- During extended deceleration, in order to prevent damage to the catalytic converters

Fuel Trim

The ECM controls the air/fuel metering system in order to provide the best possible combination of driveability, fuel economy, and emission control. The ECM monitors the heated oxygen sensor (HO2S) signal voltage while in Closed Loop and regulates the fuel delivery by adjusting the pulse width of the injectors based on this signal.

The ideal fuel trim values are around 0 percent for both short and long term fuel trim. A positive fuel trim value indicates the ECM is adding fuel in order to compensate for a lean condition by increasing the pulse width. A negative fuel trim value indicates that the ECM is reducing the amount of fuel in order to compensate for a rich condition by decreasing the pulse width. A change made to the fuel delivery changes the long and short term fuel trim values. The short term fuel trim values change rapidly in response to the HO2S signal voltage. These changes fine tune the engine fueling. The long term fuel trim makes coarse adjustments to fueling in order to recenter and restore control to short term fuel trim. A scan tool can be used to monitor the short and long term fuel trim values. The long term fuel trim diagnostic is based on an average of several of the long term speed load learn cells. The ECM selects the cells based on the engine speed and engine load. If the ECM detects an excessively lean or rich condition, the ECM will set a fuel trim diagnostic trouble code (DTC).

Knock sensor system description

Circuit/System Description

The knock sensor system enables the engine control module (ECM) to control the ignition timing for the best possible performance while protecting the engine from potentially damaging levels of detonation. The ECM uses the knock sensor system to test for abnormal engine noise that may indicate detonation, also known as spark knock.

Sensor Description

The knock sensor system uses a flat response sensor. The sensor uses a piezo-electric crystal technology that produces an AC voltage signal of varying amplitude and frequency based on the engine vibration or noise level.

The amplitude and frequency are dependant upon the level of knock that the knock sensor detects. The knock sensor is connected to the engine control module (ECM) by a signal circuit and a low reference circuit. Both knock sensor circuits are protected from electromagnetic interference by a shielding ground circuit. The shielding ground circuit is grounded through the ECM.

The ECM learns a minimum noise level, or back ground noise, at idle from the knock sensor and uses calibrated values for the rest of the engine speed range. The control module uses the minimum noise level to calculate a noise channel. A normal knock sensor signal is within the noise channel. As engine speed and load changes, the noise channel upper and lower parameters change to accommodate the normal knock sensor signal, keeping the signal within the channel. In order to determine which cylinders are knocking, the ECM only uses knock sensor signal information when each cylinder is near top dead center of the firing stroke. If knock is present, the ECM detects that the signal is outside of the noise channel.

If the ECM detects that knock is present, the ECM retards the ignition timing to attempt to eliminate the knock.

The ECM always attempts to adjust back to a zero compensation level, or no spark retard. An abnormal knock sensor signal stays outside of the noise channel or will not be present. Knock sensors diagnostics are calibrated to detect faults with the knock sensor circuitry inside the ECM, the knock sensor wiring, or the knock sensor voltage output. Some diagnostics are also calibrated to detect constant noise from an outside influence such as a loose, damaged component, or excessive engine mechanical noise.

THROTTLE ACTUATOR CONTROL (TAC) SYSTEM DESCRIPTION

.gif)

Fig. 3: Throttle Actuator Control (TAC) System

The engine control module (ECM) is the control center for the throttle actuator control (TAC) system. The ECM determines the driver's intent based on input from the accelerator pedal position sensors, then calculates the appropriate throttle response based on the throttle position sensors. The ECM achieves throttle positioning by providing a pulse width modulated voltage to the throttle actuator motor. The throttle blade is spring loaded in both directions, and the default position is slightly open.

Modes Of Operation

Normal Mode

During the operation of the TAC system, several modes, or functions, are considered normal. The following modes may be entered during normal operations:

- Minimum pedal value-At key-up, the ECM updates the learned minimum pedal value.

- Minimum throttle position values-At key-up, the ECM updates the learned minimum throttle position value. In order to learn the minimum throttle position value, the throttle blade is moved to the Closed position.

- Ice break mode-If the throttle blade is not able to reach a predetermined minimum throttle position, the ice break mode is entered. During the ice break mode, the ECM commands the maximum pulse width several times to the throttle actuator motor in the closing direction.

- Minimum pedal value-At key-up, the ECM updates the learned minimum pedal value.

- Battery saver mode-After a predetermined time without engine RPM, the ECM commands the Battery Saver mode. During the Battery Saver mode, the TAC module removes the voltage from the motor control circuits, which removes the current draw used to maintain the idle position and allows the throttle to return to the spring loaded default position.

Reduced Engine Power Mode

When the ECM detects a condition with the TAC system, the ECM may enter a reduced engine power mode.

Reduced engine power may cause one or more of the following conditions:

- Acceleration limiting-The ECM will continue to use the accelerator pedal for throttle control, however, the vehicle acceleration is limited.

- Limited throttle mode-The ECM will continue to use the accelerator pedal for throttle control, however, the maximum throttle opening is limited.

- Throttle default mode-The ECM will turn OFF the throttle actuator motor, and the throttle will return to the spring loaded default position.

- Forced idle mode-The ECM will perform the following actions:

- Limit engine speed to idle positioning the throttle position, or by controlling the fuel and spark if the throttle is turned OFF.

- Ignore the accelerator pedal input.

- Engine shutdown mode-The ECM will disable fuel and de-energize the throttle actuator

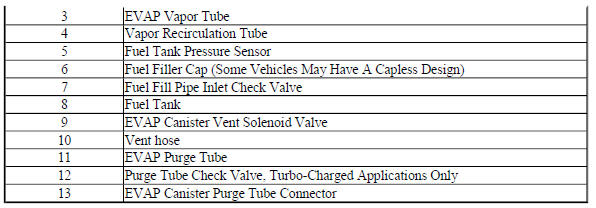

TURBOCHARGER SYSTEM DESCRIPTION

.gif)

Fig. 4: Turbocharger System Description Diagram

Turbocharger Description and Operation

A turbocharger is a forced induction device used for increasing power output of an internal combustion engine.

By using the exhaust gas forces to compress intake air, a turbocharged engine is more powerful and efficient than a naturally aspirated engine with the same displacement. The dual-scroll turbocharger is mounted on the exhaust manifold and the lightweight turbine is driven by the waste energy generated by the flow of the exhaust gases. The turbine is connected by a shaft to the compressor which is mounted in the induction system of the engine. The compressor vanes compress the intake air above atmospheric pressure, thereby greatly increasing the density of the air entering the engine.

The turbocharger incorporates a wastegate that is controlled by the ECM, by means of a pulse width modulated (PWM) solenoid, to regulate the pressure ratio of the compressor. An integral turbocharger bypass valve, controlled by the ECM through a remotely mounted solenoid, is used to prevent compressor surging and damage by opening during abrupt closed throttle conditions. The bypass valve opens during closed throttle deceleration conditions, which allows the air to recirculate in the turbocharger and maintain compressor speed.

During a wide open throttle command, the bypass valve closes to optimize turbo response.

The turbocharger is connected to the engine oiling system by a supply and drain tube and synthetic oil is installed at the factory. Synthetic oil is required for its friction-reducing capabilities and high-temperature performance. There is a cooling system circuit in the turbocharger that utilizes the engine coolant to further reduce operating temperatures.

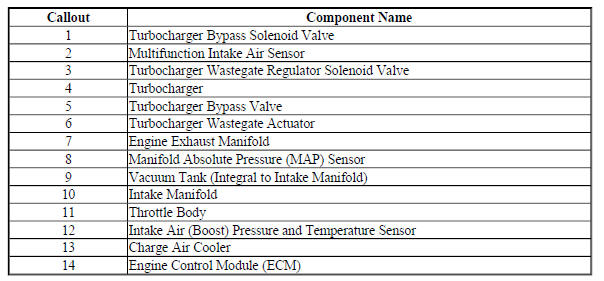

Turbocharger Wastegate Solenoid Valve

The wastegate valve opens and closes a bypass passage beside the turbine wheel. A spiral spring works in the closing direction while the pressure in the diaphragm works in the opening direction. The ECM supplies a PWM signal to the solenoid valve, which then allows pressure from the turbo to come through. When the pressure overcomes the spring force the actuator rod begins to move, opening the wastegate valve to a corresponding degree. The ECM changes wastegate valve opening by varying the PWM signal, which regulates the turbine speed.

At low loads, the wastegate valve is closed. All the exhaust gas then passes through the turbine. At high loads, the volume of exhaust gas is greater, which makes the turbine wheel rotate faster. This delivers a greater air displacement to the engine.

When the air displacement becomes so large that the current air mass per combustion cannot be controlled with the throttle alone, the turbo must be regulated. This is done by opening the wastegate valve so that some of the exhaust gas passes through the wastegate. Consequently, this gas does not contribute to driving the turbine and the turbine speed will be regulated so that the turbo air displacement will be correct.

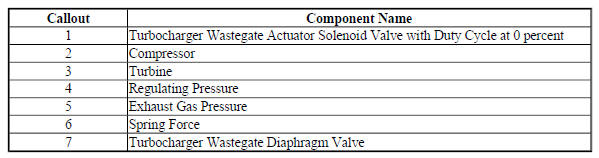

When certain DTCs are set the ECM will limit the amount of available boost pressure. Limiting boost pressure is accomplished by the ECM controlling the wastegate actuator solenoid valve and maintaining the duty cycle at 0 %. This means that the ECM will not actively close the wastegate during greater engine loads. The system at this point is limited to mechanical boost. Mechanical boost means that the wastegate will still move, but the amount of motion is limited by the mechanical properties of the return spring within the diaphragm valve, the pneumatic properties of the actuator, and the physics of the exhaust gas flow in the exhaust system.

The turbocharger wastegate diaphragm valve assembly has a threaded rod and nut that connects the diaphragm of the valve to the wastegate. This rod is adjusted to factory specifications and is not adjustable.

The following diagrams illustrate the turbocharger wastegate closed and open conditions:

Turbocharger Wastegate Closed

.gif)

Fig. 5: TC Wastegate Closed

Turbocharger Wastegate Open

.gif)

Fig. 6: TC Wastegate Open

The wastegate is completely closed at idle. All of the exhaust energy is passing through the turbine.

During normal operation, when wide open throttle is requested at lower engine speeds, the ECM commands the wastegate solenoid with a duty cycle of 100 % to minimize any turbo lag. During engine loads in the middle and upper RPM ranges, the ECM commands the solenoid with a duty cycle of about 65 %.

Turbocharger Bypass Solenoid Valve

The turbocharger bypass valve prevents the turbo from exceeding the pump limit at low flow and high pressure.

This occurs when the engine is running with a load and the throttle suddenly closes. In this case, flow is almost null and pressure is very high. This not only is damaging to the turbocharger, but also generates noise and decelerates turbine speed. The ECM supplies a voltage signal to the solenoid valve output driver, which regulates the open or closed valve position.

Accelerator Pedal Depressed

The bypass valve is closed. The force in the return spring integrated in the valve presses the valve cone against its seat in the turbo housing. The valve is turned OFF.

Accelerator Pedal Released

In order to avoid pressure spikes in the intake manifold and unloading or overrunning the turbo, the ECM sends a voltage signal to the bypass valve, which will then open. The compressed air on the pressure side of the turbo is led to the intake via the open valve. When the pressure drops, the turbine speed can be kept relatively high and the turbocharger is prevented from exceeding the pump limit.

Charge Air Cooler

The turbocharger is supported by an air-to-air charge air cooler system, which uses fresh air drawn through a heat exchanger to reduce the temperature of the warmer compressed air forced through the intake system. Inlet air temperature can be reduced by up to 100ºC (180ºF), which enhances performance. This is due to the higher density of oxygen in the cooled air, which promotes optimal combustion. The charge air cooler is connected to the turbocharger and to the throttle body by flexible ductwork that requires the use of special high torque fastening clamps. In order to prevent any type of air leak when servicing the ductwork, the tightening specifications and proper positioning of the clamps is critical, and must be strictly adhered to.