Buick Encore: Object Detection and Pedestrian Protection - Diagnostic information and procedures

DTC B094C: Right side object detection control module

DIAGNOSTIC CODE INDEX

.jpg)

.jpg)

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptor

DTC B094C

Right Side Object Detection Control Module

For symptom byte information, refer to Symptom Byte List .

Circuit/System Description

B218R Side Object Sensor Module - Right communicates on a private communication data bus with the B218L Side Object Sensor Module - Left. The B218L Side Object Sensor Module - Left is the master and can set this code if the B218R Side Object Sensor Module - Right determines it has an internal fault. DTC U18A6 will set if the left module is unable to communicate with the right side module.

Conditions for Running the DTC

Ignition ON.

Conditions for Setting the DTC

The B218R Side Object Sensor Module - Right has detected an internal malfunction.

Action Taken When the DTC Sets

- The side object sensor system is disabled..

- The DIC will display "Service Side Detection System".

Conditions for Clearing the DTC

- A current DTC clears when the malfunction is no longer present.

- A history DTC clears when the control module ignition cycle counter reaches the reset threshold of 40, without a repeat of the malfunction.

Diagnostic Aids

- The modules are not identical and cannot be swapped from side to side.

- This DTC may be stored as a history DTC without affecting the operation of the B218R Side Object Sensor Module - Right.

- Do not replace B218R Side Object Sensor Module - Right based only on DTC B094C being set in history.

- If DTC B094C is set as current, replace the B218R Side Object Sensor Module - Right.

- B218R Side Object Sensor Module - Right communicates on a private communication data bus with the B218L Side Object Sensor Module - Left. If programming is needed for module replacement, you must program B218L Side Object Sensor Module - Left which will then in turn program B218R Side Object Sensor Module - Right.

Reference Information

Schematic Reference

Object Detection Schematics (Encore), Object Detection Schematics (Encore)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

Description and Operation

Object Detection Description and Operation (Rearvision Camera, UVC), Object Detection Description and Operation (Rear Park Assist, UD7), Object Detection Description and Operation (Side Blind Zone Alert, UFT), Object Detection Description and Operation (Rear Cross Traffic Alert, UFG)

Electrical Information Reference

- Circuit Testing

- Connector Repairs

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

Scan Tool Reference

Control Module References for scan tool information

Circuit/System Verification

- Ignition ON.

- Verify that B094C is not set.

- If DTC is set

Replace the B218R Side Object Sensor Module - Right.

- If the DTC is not set

- All OK.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

Control Module References for side object sensor module replacement, programming and setup.

DTC B0954, B0955, B0956, OR B0957: Parking assist front sensor

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptors

DTC B0954

Parking Assist Front Sensor Left Corner Circuit

DTC B0955

Parking Assist Front Sensor Left Middle Circuit

DTC B0956

Parking Assist Front Sensor Right Middle Circuit

DTC B0957

Parking Assist Front Sensor Right Corner Circuit

For symptom byte information, refer to Symptom Byte List .

Diagnostic Fault Information

.jpg)

.gif)

Circuit/System Description

The object sensors are 3-wire sensors that are used to determine the distance between the vehicle and an object of interest. The front and rear parking assist control module supplies 8 V to the object sensors via the 8 V reference circuit and provides ground via the low reference circuit. The front and rear parking assist control module triggers the sensors in a sequential loop. After each sensor transmits, the front and rear parking assist control module uses the sensor echo received through the signal circuit to calculate the distance and position of an object.

Conditions for Running the DTC

Ignition ON

The park assist is activated. The activation takes place through putting in the reverse gear or through operating the park assist switch.

Conditions for Setting the DTC

B0954 01, B0955 01, B0956 01, or B0957 01

The front and rear parking assist control module has detected the voltage at the sensor circuit is greater than 11.5 V or the object sensor is not grounded.

B0954 06, B0955 06, B0956 06, or B0957 06

The front and rear parking assist control module has detected the voltage at the sensor circuit is less than 0.5 V.

B0954 08, B0955 08, B0956 08, or B0957 08

The front and rear parking assist control module has received an invalid signal.

B0954 21, B0955 21, B0956 21, or B0957 21

The object sensor determines no change in the position of an object while the vehicle is in motion

B0954 3A, B0955 3A, B0956 3A, or B0957 3A

The front and rear parking assist control module determines the wrong sensor type is installed.

Action Taken When the DTC Sets

- The parking assist is disabled.

- The driver information center displays SERVICE PARK ASSIST.

Conditions for Clearing the DTC

The condition for setting the DTC is no longer present.

Reference Information

Schematic Reference

Object Detection Schematics (Encore), Object Detection Schematics (Encore)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

Description and Operation

Object Detection Description and Operation (Rearvision Camera, UVC), Object Detection Description and Operation (Rear Park Assist, UD7), Object Detection Description and Operation (Side Blind Zone Alert, UFT), Object Detection Description and Operation (Rear Cross Traffic Alert, UFG)

Electrical Information Reference

- Circuit Testing

- Connector Repairs

- Testing for Intermittent Conditions and Poor Connections Wiring Repairs

Scan Tool Reference

Control Module References for scan tool information

Circuit/System Verification

- Ignition ON.

- Verify that DTC B1405 is not set.

- If the DTC is set

Refer to DTC B1405 (Rear Park Assist - UD7), DTC B1405 (Front and Rear Park Assist - UD5)

- If the DTC is not set

- Verify that DTC B0954 01, B0955 01, B0956 01, B0957 01 B0954 21, B0955 21, B0956 21 or B0957 21 is not set.

- If the DTC is set

- Verify the appropriate B78 Front Object Sensor is free of contamination from snow, mud, dirt, slush or ice.

- If contaminated, clean sensor.

- If there is no contamination

- Refer to Circuit/System Testing.

- If the DTC is not set

- Verify that DTC B0954 3A, B0955 3A, B0956 3A or B0957 3A is not set.

- If the DTC is set

Replace the B78 Front Object Sensor with the correct sensor type.

- If the DTC is not set

- Ignition ON, transmission in REVERSE.

- Verify the scan tool Parking Assist System Status parameter displays Enabled.

- If the Parking Assist System displays Disabled

Refer to Circuit/System Testing.

- If the Parking Assist System displays Enabled

- All OK

Circuit/System Testing

- Ignition OFF, scan tool disconnected, disconnect the harness at the

appropriate B78 Front Object Sensor.

It may take up to 2 min for all vehicle systems to power down.

- Test for less than 10 ohms between the low reference circuit terminal 2 and ground.

- If 10 ohms or greater

- Ignition OFF, disconnect the harness connector X3 at the K41 Front and Rear Parking Assist Control Module.

- Test for less than 2 ohms in the low reference circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms replace the K41 Front and Rear Parking Assist Control Module.

- If less than 10 ohms

- Ignition ON.

- Test for 7.5-9.5 V between the 8 V reference circuit terminal 1 and ground.

- If less than 7.5 V

- Ignition OFF, disconnect the harness connector at the K41 Front and Rear Parking Assist Control Module.

- Test for infinite resistance between the 8 V reference circuit and ground.

- If less than infinite resistance, repair the short to ground on the

circuit.

If infinite resistance

- Test for less than 2 ohms in the 8 V reference circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K41 Front and Rear Parking Assist Control Module.

- If greater than 9.5 V

- Ignition OFF, disconnect the harness connector at the K41 Front and Rear Parking Assist Control Module, ignition ON.

- Test for less than 1 V between the 8 V reference circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V, replace the K41 Front and Rear Parking Assist Control Module.

- If between 7.5-9.5 V

- Ignition OFF, remove the appropriate B78 Front Object Sensor and switch locations with another properly operating sensor. Connect harness connector at both sensors. Ignition ON.

- Verify the DTC is set for the new location in which the malfunctioning sensor is installed.

- If DTC set for the new location

Replace the malfunctioning B78 Front Object Sensor.

- If DTC set for the original location

- Ignition OFF, disconnect the harness connector at the K41 Front and Rear Parking Assist Control Module, ignition ON.

- Test for less than 1 V between the signal circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V

- Ignition OFF.

- Test for infinite resistance between the signal circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance

- Test for less than 2 ohms in the circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K41 Front and Rear Parking Assist Control Module.

- If no DTC set

- All OK.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Front Object Alarm Sensor Housing Replacement

- Rear Parking Assist Alarm Sensor Replacement

- Control Module References for front and rear parking assist control module replacement, programming and setup.

DTC B0958, B0959, B0960, OR B0961: Parking assist rear sensor

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptors

DTC B0958

Parking Assist Rear Sensor Left Corner Circuit

DTC B0959

Parking Assist Rear Sensor Left Middle Circuit

DTC B0960

Parking Assist Rear Sensor Right Middle Circuit

DTC B0961

Parking Assist Rear Sensor Right Corner Circuit

For symptom byte information, refer to Symptom Byte List .

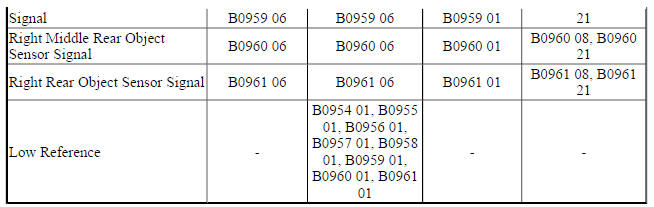

Diagnostic Fault Information

.jpg)

Circuit/System Description

The object sensors are 3-wire sensors that are used to determine the distance between the vehicle and an object of interest. The front and rear parking assist control module supplies 8 V to the object sensors via the 8 V reference circuit and provides ground via the low reference circuit. The front and rear parking assist control module triggers the sensors in a sequential loop. After each sensor transmits, the front and rear parking assist control module uses the sensor echo received through the signal circuit to calculate the distance and position of an object.

Conditions for Running the DTC

- Ignition ON

- The parking assist is activated. The activation takes place through putting in the reverse gear or through operating the park assist switch.

Conditions for Setting the DTC

B0958 01, B0959 01, B0960 01, or B0961 01

The front and rear parking assist control module has detected the voltage at the sensor circuit is greater than 11.5 V or the object sensor is not grounded.

B0958 06, B0959 06, B0960 06, or B0961 06

The front and rear parking assist control module has detected the voltage at the sensor circuit less than 0.5 V.

B0958 08, B0959 08, B0960 08, or B0961 08

The front and rear parking assist control module has received an invalid signal.

B0958 21, B0959 21, B0960 21, or B0961 21

The object sensor determines no change in the position of an object while the vehicle is in motion.

B0958 3A, B0959 3A, B0960 3A, or B0961 3A

The front and rear parking assist control module determines the wrong sensor type is installed.

Action Taken When the DTC Sets

- The parking assist is disabled.

- The driver information center displays SERVICE PARK ASSIST.

Conditions for Clearing the DTC

The condition for setting the DTC is no longer present.

Reference Information

Schematic Reference

Object Detection Schematics (Encore), Object Detection Schematics (Encore)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

Description and Operation

Object Detection Description and Operation (Rearvision Camera, UVC), Object Detection Description and Operation (Rear Park Assist, UD7), Object Detection Description and Operation (Side Blind Zone Alert, UFT), Object Detection Description and Operation (Rear Cross Traffic Alert, UFG)

Electrical Information Reference

- Circuit Testing

- Connector Repairs

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

Scan Tool Reference

Control Module References for scan tool information

Circuit/System Verification

- Ignition ON.

- Verify that DTC B1405 is not set.

- If the DTC is set

Refer to DTC B1405 (Rear Park Assist - UD7), DTC B1405 (Front and Rear Park Assist - UD5)

- If the DTC is not set

- Verify that DTC B0958 01, B0959 01, B0960 01, B0961 01, B0958 21, B0959 21, B0960 21 or B0961 21 is not set.

- If the DTC is set

- Verify the B78 Rear Object Sensors are not contaminated with snow, mud, dirt, slush, or ice.

- If contaminated, clean sensor.

- If there is no contamination

- Refer to Circuit/System Testing.

- If the DTC is not set

- Verify that DTC B0958 3A, B0959 3A, B0960 3A or B0961 3A is not set.

- If the DTC is set

Replace the B78 Rear Object Sensor with the correct sensor type.

- If the DTC is not set

- Ignition ON, transmission in REVERSE.

- Verify the scan tool Parking Assist System Status parameter displays Enabled.

- If the Parking Assist System displays Disabled

Refer to Circuit/System Testing.

- If the Parking Assist System displays Enabled

- All OK.

Circuit/System Testing

- Ignition OFF, scan tool disconnected, disconnect the harness at the

appropriate B78 Rear Object Sensor.

It may take up to 2 min for all vehicle systems to power down.

- Test for less than 10 ohms between the low reference circuit terminal 2 and ground.

- If 10 ohms or greater

- Ignition OFF, disconnect the harness connector X2 at the K41 Front and Rear Parking Assist Control Module.

- Test for less than 2 ohms in the low reference circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms replace the K41 Front and Rear Parking Assist Control Module.

- If less than 10 ohms

- Ignition ON.

- Test for 7.5-9.5 V between the 8 V reference circuit terminal 1 and ground.

- If less than 7.5 V

- Ignition OFF, disconnect the harness connector at the K41 Front and Rear Parking Assist Control Module.

- Test for infinite resistance between the 8 V reference circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance

- Test for less than 2 ohms in the 8 V reference circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K41 Front and Rear Parking Assist Control Module.

- If greater than 9.5 V

- Ignition OFF, disconnect the harness connector at the K41 Front and Rear Parking Assist Control Module, ignition ON.

- Test for less than 1 V between the 8 V reference circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V, replace the K41 Front and Rear Parking Assist Control Module.

- If between 7.5-9.5 V

- Ignition OFF, remove the appropriate B78 Rear Object Sensor and switch locations with another properly operating sensor. Connect harness connector at both sensors. Ignition ON.

- Verify the DTC is set for the new location in which the malfunctioning sensor is installed.

- If DTC set for the new location

Replace the malfunctioning B78 Rear Object Sensor.

- If DTC set for the original location

- Ignition OFF, disconnect the harness connector at the K41 Front and Rear Parking Assist Control Module, ignition ON.

- Test for less than 1 V between the signal circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V

- Ignition OFF.

- Test for infinite resistance between the signal circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance

- Test for less than 2 ohms in the circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K41 Front and Rear Parking Assist Control Module.

- If no DTC set

- All OK.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Rear Parking Assist Alarm Sensor Replacement

- Control Module References for front and rear parking assist control module replacement, programming and setup.

DTC B0987: Vehicle direction camera indicator

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptors

DTC B0987 01

Vehicle Direction Camera Indicator Circuit Short to Battery

DTC B0987 06

Vehicle Direction Camera Indicator Circuit Low Voltage/Open

DTC B0987 0B

Vehicle Direction Camera Indicator Circuit High Current

Diagnostic Fault Information

.jpg)

Circuit/System Description

The lane departure warning is enabled and disabled through the lane departure warning switch located in the center console. When enabled, the frontview camera module will illuminate the indicator located in the switch.

The BCM supplies voltage to the indicator from the lighting dimming circuit. The frontview camera module turns on the indicator by proving the ground.

Conditions for Running the DTC

Ignition ON.

Conditions for Setting the DTC

B0987 01

The frontview camera module detects a short to voltage in the control circuit.

B0987 06

The frontview camera module detects a short to ground or an open/high resistance in the control circuit.

B0987 0B

The active safety control module detects high current in the control circuit.

Action Taken When the DTC Sets

- Lane departure warning is disabled

- The driver information center displays "Service Front Camera".

Conditions for Clearing the DTC

The condition for setting the DTC is no longer present.

Reference Information

Schematic Reference

Object Detection Schematics (Encore), Object Detection Schematics (Encore)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

Description and Operation

Object Detection Description and Operation (Rearvision Camera, UVC), Object Detection Description and Operation (Rear Park Assist, UD7), Object Detection Description and Operation (Side Blind Zone Alert, UFT), Object Detection Description and Operation (Rear Cross Traffic Alert, UFG)

Electrical Information Reference

- Circuit Testing

- Connector Repairs

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

Scan Tool Reference

Control Module References for scan tool information

Circuit/System Verification

- Ignition ON.

- Verify DTC B356A is not set.

- If the DTC is set

Refer to DTC B356A

- If the DTC is not set

- Verify the lane departure warning indicator turns ON and OFF when pressing and releasing the lane departure warning switch.

- If the indicator does not turn ON and OFF

Refer to Circuit/System Testing.

- If the indictor turns ON and OFF

- All OK.

Circuit/System Testing

- Ignition OFF, and all vehicle systems OFF, disconnect the harness connector at the S48E Multifunction Switch - Center Console, ignition ON.

- Test for 9.1 - 12.6 V between the dimming control circuit terminal 8 and ground.

NOTE: Verify interior lighting dimming is turned all the way up.

- If less than 9.1 V

- Ignition OFF, disconnect the X1 harness connector at the K9 Body Control Module.

- Test for infinite resistance between the control circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance

- Test for less than 2 ohms in the control circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, refer to Interior Backlighting Malfunction .

- If greater than 12.6 V

- Ignition OFF, disconnect the X1 harness connector at the K9 Body Control Module, ignition ON.

- Test for less than 1 V between the control circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V, refer to Interior Backlighting Malfunction .

- If between 9.1- 12.6 V

- Ignition OFF, disconnect the harness connector at the K109 Frontview Camera Module, ignition ON.

- Test for less than 1 V between the control circuit terminal 6 and ground.

- If 1 V or greater

Repair the short to voltage on the circuit.

- If less than 1 V

- Ignition OFF.

- Test for infinite resistance between the control circuit terminal 6 and ground.

- If less than infinite resistance

Repair the short to ground on the circuit.

- If infinite resistance

- Test for less than 5 ohms between the K109 Frontview Camera Module terminal 4 and S48E Multifunction Switch - Center Console circuit terminal 6.

- If greater than 5 ohms

Repair the open/high resistance in the circuit.

- If less than 5 ohms

- Test or replace the S48E Multifunction Switch - Center Console.

- Verify the lane departure switch Indicator turns ON and OFF when pressing and releasing the lane departure warning switch.

- If indicator does not turn on and off

Replace K109 Frontview Camera Module.

- If indicator turns on and off

- All OK.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair

- Accessory Switch Replacement (Encore) , Accessory Switch Replacement (Encore)

- Control Module References for frontview camera module replacement, programming and setup.

DTC B1011: System disabled information stored malfunction

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptor

DTC B1011 00

System Disabled Information Stored Malfunction

Circuit/System Description

The frontview camera module permanently monitors the serial data bus for error messages. When a malfunction is detected by the frontview camera module, the system will be disabled and an error message will be stored in the frontview camera module disable history buffer which is used to store information about the front camera features that are disabled.

Conditions for Running the DTC

- Ignition ON

- Frontview camera enabled

Conditions for Setting the DTC

The frontview camera module detects a malfunction.

Action Taken When the DTC Sets

- The frontview camera module is disabled.

- The frontview camera module disable history buffer stores information why the system was disabled.

Conditions for Clearing the DTC

The condition for setting the DTC is no longer present.

Diagnostic Aids

The frontview camera module disable history buffers are used to store information about the frontview camera module features that are disabled. The buffers will only update if the disable condition changes.

Example: If the data received from the steering wheel angle sensor is Invalid across many ignition cycles then it will only appear in 1 history buffer and not all history buffers. If this condition is the current reason why the frontview camera module is disabled then it will be set in frontview camera module disable history buffer 1. If a new reason occurs, such as vehicle speed validity is invalid, then the invalid steering wheel angle sensor fault will shift into disable history buffer 2 and vehicle speed validity invalid will be in disable history buffer 1. Since there are only 4 disable history buffers, the invalid steering wheel angle sensor will age out if 4 other disable reasons occur since the last invalid steering wheel angle sensor event occurred. Frontview camera module disable history buffer 1 contains the current reason that one of the frontview camera module features is disabled.

The frontview camera module disable history buffers can display the following values:

- Lane Departure Warning Indicator Malfunction

- Lane Departure Warning Switch Malfunction

- Camera Obstructed

- Accelerator Pedal Position Out of Range

- Driven Wheel Speed Signal Invalid

- Non-Driven Wheel Speed Signal Invalid

- Brake Pedal Moderate Travel Signal Invalid

- Brake Pedal Initial Travel Position Achieved

- Lost Communication with Steering Wheel Angle Sensor Module

- Invalid Data Received From Steering Wheel Angle Sensor Module

- Forward Collision Alert Switch Malfunction

- Clutch Pedal Position (CPP) Sensor Performance

- Clutch Pedal Position (CPP) Sensor Performance

- Transmission Gear Engaged

- Acceleration Sensor Longitudinal Signal

- Invalid Data Received From Yaw Rate Sensor Module

- Power Mode Controlled by Backup Device

- System Power Mode

- Overvoltage

- Undervoltage

- Undefined

Reference Information

Schematic Reference

Object Detection Schematics (Encore), Object Detection Schematics (Encore)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

Description and Operation

Object Detection Description and Operation (Rearvision Camera, UVC), Object Detection Description and Operation (Rear Park Assist, UD7), Object Detection Description and Operation (Side Blind Zone Alert, UFT), Object Detection Description and Operation (Rear Cross Traffic Alert, UFG)

Electrical Information Reference

- Circuit Testing

- Connector Repairs

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

Scan Tool Reference

Control Module References for scan tool information

Circuit/System Verification

NOTE: Do not replace K109 Frontview Camera Module for this DTC. DTC B1011 is an information DTC.

- gnition ON.

- Verify no other DTC is set except for DTC B1011.

- If any other DTCs are set

Diagnose those first. Refer to Diagnostic Trouble Code (DTC) List - Vehicle .

- If no other DTCs are set

NOTE: When referring to Frontview Camera Disable History, some items such as Non-Driven Wheel Speed Signal Invalid and Driven Wheel Speed Signal Invalid may routinely be stored without B1011 being set. If B1011 has not set, disregard any information stored in the buffers as it is not indicative of a problem.

- Refer to Diagnostic Aids and Frontview Camera Disable History for what caused B1011 to set. Diagnose the system that set the malfunction

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

Control Module References for frontview camera module programming and setup

DTC B1015: Vehicle identification number information malfunction

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptor

DTC B1015 00

Vehicle Identification Number Information Malfunction

Circuit/System Description

When the ignition is turned ON, the front and rear parking assist control module and frontview camera module receives the vehicle identification number (VIN) from the body control module. The modules will compare the VIN received to the VIN stored in memory.

Conditions for Running the DTC

Ignition voltage is between 9-16 V.

Conditions for Setting the DTC

The stored VIN does not match the received VIN.

Action Taken When the DTC Sets

- The parking assist system, lane departure warning system, and forward collision alert system is disabled.

- The driver information center displays SERVICE PARK ASSIST or SERVICE LANE DEPARTURE SYSTEM.

Conditions for Clearing the DTC

The stored VIN matches the VIN stored in the body control module.

Reference Information

Schematic Reference

Object Detection Schematics (Encore), Object Detection Schematics (Encore)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

Description and Operation

Object Detection Description and Operation (Rearvision Camera, UVC), Object Detection Description and Operation (Rear Park Assist, UD7), Object Detection Description and Operation (Side Blind Zone Alert, UFT), Object Detection Description and Operation (Rear Cross Traffic Alert, UFG)

Electrical Information Reference

- Circuit Testing

- Connector Repairs

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

Scan Tool Reference

Control Module References for scan tool information

Circuit/System Verification

- Ignition ON.

- Verify DTC B1015 is not.

- If DTC B1015 is set

- Program the control module the DTC originally set in.

- Verify the DTC does not set.

- If the DTC is sets, replace the control module the DTC set in.

- If the DTC does not set

- All OK

- If DTC B1015 is not set

- All OK

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair

Control Module References for the front and rear parking assist control module and frontview camera module replacement, programming and setup.

DTC B101D (with side blind zone alert, uft): electronic control unit hardware

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptor

DTC B101D

Electronic Control Unit Hardware

For symptom byte information, refer to Symptom Byte List .

Circuit/System Description

The side detection system uses two modules B218L Side Object Sensor Module - Left and B218R Side Object Sensor Module - Right. The left module is the master and is on the vehicle's serial data bus and communicates to the right module on a private bus. The internal fault detection is handled inside the B218L Side Object Sensor Module - Left. No external circuit diagnosis is involved.

Conditions for Setting the DTC

- The B218L Side Object Sensor Module - Left runs the program to detect an internal fault when power up is commanded.

Conditions for Setting the DTC

The B218L Side Object Sensor Module - Left has detected an internal malfunction

Action Taken When the DTC Sets

- The side object sensor system is disabled.

- The driver information center displays SERVICE SIDE DETECTION SYSTEM

Conditions for Clearing the DTC

- A current DTC clears when the malfunction is no longer present.

- A history DTC clears when the device ignition cycle counter reaches the reset threshold of 50, without a repeat of the malfunction.

Diagnostic Aids

- This DTC may be stored as a history DTC without affecting the operation of the B218L Side Object Sensor Module - Left.

- Do not replace B218L Side Object Sensor Module - Left based only on DTC B101D being set in history.

- If DTC B101D is set as current, replace the B218L Side Object Sensor Module - Left.

- Since the left module is the master, if it is replaced, there still may be a problem with the right side as the module may have been unable to report it. Once the left module is replaced, check DTCs and verify operation of the system to assure proper functionality.

Reference Information

Schematic Reference

- Data Communication Schematics (Encore) , Data Communication Schematics (Encore)

- Control Module References

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

Description and Operation

Data Link Communications Description and Operation

Electrical Information Reference

- Circuit Testing

- Connector Repairs

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

Scan Tool Reference

Control Module References for scan tool information

Circuit/System Verification

- Ignition ON.

- Verify DTC B101D is not set.

- If DTC B101D is set

- Replace the B218L Side Object Sensor Module - Left.

- Verify no new DTCs set and side object system operates properly

- If there are new DTCs refer to Diagnostic Trouble Code (DTC) List - Vehicle , or if the system does not operate properly, refer to Side Object System Malfunction.

- If there are no new DTCs and the side object system operates properly

- If DTC B101D is not set

- All OK

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

Control Module References for B218L Side Object Sensor Module - Left replacement, programming and setup.

DTC B1405 (Rear park assist - ud7): control module voltage reference output 2

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptors

DTC B1405 02

Control Module Voltage Reference Output 2 Circuit Short to Ground

DTC B1405 03

Control Module Voltage Reference Output 2 Circuit Low Voltage

DTC B1405 07

Control Module Voltage Reference Output 2 Circuit High Voltage

Diagnostic Fault Information

.jpg)

Circuit/System Description

The object sensors are 3-wire sensors that are used to determine the distance between the vehicle and an object of interest. The front and rear parking assist control module supplies 8 V to the object sensors via the object sensor supply voltage circuit and provides ground via the object sensor low reference circuit. The front and rear parking assist control module triggers the sensors in a sequential loop. After each sensor transmits, the front and rear parking assist control module uses the sensor echo received through the object sensor signal circuit to calculate the distance and position of an object.

Conditions for Running the DTC

- Ignition ON, engine RUNNING

- Transmission in REVERSE

Conditions for Setting the DTC

B1405 02

The rear parking assist control module has detected the object sensor supply voltage circuit is shorted to ground.

B1405 03

The rear parking assist control module has detected the object sensor supply voltage circuit is less than 7.2 V.

B1405 07

The rear parking assist control module has detected the object sensor supply voltage circuit is greater than 9.2 V.

Action Taken When the DTC Sets

- The parking assist system is disabled.

- The driver information center displays SERVICE PARK ASSIST.

Conditions for Clearing the DTC

The condition for setting the DTC is no longer present.

Reference Information

Schematic Reference

Object Detection Schematics (Encore), Object Detection Schematics (Encore)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

Description and Operation

Object Detection Description and Operation (Rearvision Camera, UVC), Object Detection Description and Operation (Rear Park Assist, UD7), Object Detection Description and Operation (Side Blind Zone Alert, UFT), Object Detection Description and Operation (Rear Cross Traffic Alert, UFG)

Electrical Information Reference

- Circuit Testing

- Connector Repairs

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

Scan Tool Reference

Control Module References for scan tool information

Circuit/System Verification

- Ignition ON, engine running, transmission in R.

- Verify the scan tool Park Assist Sensor Reference Voltage parameter is between 7.2-9.2 V.

- If Park Assist Sensor Reference Voltage is not between 7.2-9.2 V

Refer to Circuit/System Testing

- If Park Assist Sensor Reference Voltage is between 7.2-9.2 V

- All OK.

Circuit/System Testing

- Ignition OFF, disconnect the X2 harness connector at the K41R Rear Parking Assist Control Module, ignition ON.

- Test for less than 1 V between the 8 V reference circuit terminal 4 and ground.

- If 1 V or greater

Repair the short to voltage on the circuit.

- If less than 1 V

- Ignition OFF.

- Test for infinite resistance between the 8 V reference circuit terminal 4 and ground.

- If less than infinite resistance

Repair the short to ground on the circuit.

- If infinite resistance

- Replace the K41R Rear Parking Assist Control Module.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

Control Module References for rear parking assist control module replacement, programming and setup.

DTC B1405 (Front and rear park assist - ud5): control module voltage reference output 2

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptors

DTC B1405 02

Control Module Voltage Reference Output 2 Circuit Short to Ground

DTC B1405 03

Control Module Voltage Reference Output 2 Circuit Low Voltage

DTC B1405 07

Control Module Voltage Reference Output 2 Circuit High Voltage

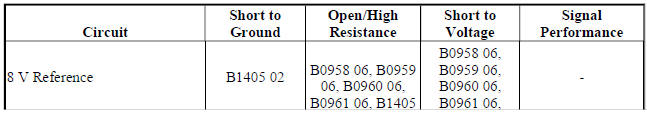

Diagnostic Fault Information

.jpg)

Circuit/System Description

The object sensors are 3-wire sensors that are used to determine the distance between the vehicle and an object of interest. The front and rear parking assist control module supplies 8 V to the object sensors via the object sensor supply voltage circuit and provides ground via the object sensor low reference circuit. The front and rear parking assist control module triggers the sensors in a sequential loop. After each sensor transmits, the front and rear parking assist control module uses the sensor echo received through the object sensor signal circuit to calculate the distance and position of an object.

Conditions for Running the DTC

- Ignition ON, engine RUNNING

- Transmission in REVERSE

Conditions for Setting the DTC

B1405 02

The front and rear parking assist control module has detected the object sensor supply voltage circuit is shorted to ground.

B1405 03

The front and rear parking assist control module has detected the object sensor supply voltage circuit is less than 7.2 V.

B1405 07

The front and rear parking assist control module has detected the object sensor supply voltage circuit is greater than 9.2 V.

Action Taken When the DTC Sets

- The parking assist is disabled.

- The driver information center displays SERVICE PARK ASSIST.

Conditions for Clearing the DTC

The condition for setting the DTC is no longer present.

Reference Information

Schematic Reference

Object Detection Schematics (Encore), Object Detection Schematics (Encore)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

Description and Operation

Object Detection Description and Operation (Rearvision Camera, UVC), Object Detection Description and Operation (Rear Park Assist, UD7), Object Detection Description and Operation (Side Blind Zone Alert, UFT), Object Detection Description and Operation (Rear Cross Traffic Alert, UFG)

Electrical Information Reference

- Circuit Testing

- Connector Repairs

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

Scan Tool Reference

Control Module References for scan tool information

Circuit/System Verification

Ignition ON, engine running, transmission in R.

Verify the scan tool Park Assist Sensor Reference Voltage parameter is between 7.2-9.2 V.

- If Park Assist Sensor Reference Voltage is not between 7.2-9.2 V

Refer to Circuit/System Testing

- If Park Assist Sensor Reference Voltage is between 7.2-9.2V

- All OK.

Circuit/System Testing

- Ignition OFF, disconnect harness connectors X2 and X3 at the K41 Front and Rear Parking Assist Control Module, ignition ON.

- Test for less than 1 V between the 8 V reference circuit terminals listed below and ground.

- Terminal 4 X2

- Terminal 1 X3

- If 1 V or greater

Repair the short to voltage on the circuit.

- If less than 1 V

- Ignition OFF.

- Test for infinite resistance between 8V reference circuit terminals listed below and ground.

- Terminal 4 X2

- Terminal 1 X3

- If less than infinite resistance

Repair the short to ground on the circuit.

- If infinite resistance

- Replace the K41 Front and Rear Parking Assist Control Module.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Front Object Alarm Sensor Housing Replacement

- Rear Parking Assist Alarm Sensor Replacement

- Control Module References for front and rear parking assist control module replacement, programming and setup.

DTC B356A: Vehicle direction warning switch circuit

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptors

DTC B356A 02

Vehicle Direction Warning Switch Circuit Short to Ground

DTC B356A 05

Vehicle Direction Warning Switch Circuit Short to Voltage

Diagnostic Fault Information

.jpg)

Circuit/System Description

The lane departure warning feature is enabled and disabled through the lane departure switch located in the left steering wheel controls switch. When enabled, the frontview camera module will illuminate the indicator located in the switch. The forward collision alert distance is adjustable using the forward collision switch located in the center console. The setting is shown in the driver information center.

When the system is operating and can detect the lane markings, the frontview camera module will request via serial data communications that the instrument panel cluster illuminate the green lane departure ready-to-assist indicator. If the frontview camera module detects that the vehicle has crossed a lane marking without the turn signal being used, the module will request that the instrument cluster flash the yellow lane departure warning indicator. An audible warning will also sound three times when the yellow instrument cluster indicator is flashing.

Conditions for Running the DTC

Ignition ON.

Conditions for Setting the DTC

DTC B356A 02

The frontview camera module has detected a short to ground for more than 10 s.

DTC B356A 05

The frontview camera module has detected a short to voltage or an open/high resistance for more than 10 s.

Action Taken When the DTC Sets

- Lane departure and forward collision warning features are disabled.

- Service Front Camera is displayed on the driver information center.

Conditions for Clearing the DTC

- The condition responsible for setting the DTC no longer exists.

- A history DTC will clear once 100 consecutive malfunction-free ignition cycles have occurred

Diagnostic Aids

Manually pressing the lane departure warning switch or forward collision alert switch for approximately 10 s will cause this DTC to set.

Reference Information

Schematic Reference

Object Detection Schematics (Encore), Object Detection Schematics (Encore)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

Description and Operation

Object Detection Description and Operation (Rearvision Camera, UVC), Object Detection Description and Operation (Rear Park Assist, UD7), Object Detection Description and Operation (Side Blind Zone Alert, UFT), Object Detection Description and Operation (Rear Cross Traffic Alert, UFG)

Electrical Information Reference

- Circuit Testing

- Connector Repairs

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

Scan Tool Reference

Control Module References for scan tool information

Circuit/System Verification

- Ignition ON.

- Verify the scan tool Lane Departure Warning Switch Status parameter changes between Open and Closed while pressing and releasing the lane departure warning switch.

- If the parameter does not change

Refer to Circuit/System Testing.

- If the parameter changes

- Verify the driver information center displays and adjusts forward collision alert setting while repeatedly pressing and releasing the forward collision switch. The setting should change cycle between far, medium, near, and off.

- If the display does not change

Refer to Circuit/System Testing.

- If the display changes

- All OK.

Circuit/System Testing

- Ignition OFF and all vehicle systems OFF, disconnect the harness connectors at the S48E Multifunction Switch - Center Console and S70L Steering Wheel Controls Switch - Left. It may take up to 2 min for all vehicle systems to power down.

- Test for less than 10 ohms between the following ground circuit terminals and ground:

- S48E Multifunction Switch - Center Console terminal 9

- S70L Steering Wheel Controls Switch - Left terminal 7

- If 10 ohms or greater

- Test for less than 2 ohms in the ground circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, repair the open/high resistance in the ground connection.

- If less than 10 ohms

- Ignition ON.

- Verify the scan tool Lane Departure Warning Switch Status parameter is Open.

- If not Open

- Ignition OFF, disconnect the harness connector at the K109 Frontview Camera Module.

- Test for infinite resistance between the S48E Multifunction Switch - Center Console signal circuit terminal 7 and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance, replace the K109 Frontview Camera Module.

- If Open

- Install a 3 A fused jumper wire between the S48E Multifunction Switch - Center Console signal circuit terminal 7 and ground.

- Verify DTC B356A 02 sets in approximately 10 s.

- If DTC does not set

- Ignition OFF, remove the jumper wire, disconnect the harness connector at the K109 Frontview Camera Module, ignition ON.

- Test for less than 1 V between the signal circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V

- Test for less than 2 ohms in the signal circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K109 Frontview Camera Module.

- If DTC sets

- Test or replace the S48E Multifunction Switch - Center Console or S70L Steering Wheel Controls Switch - Left.

Component Test

Forward Collision Alert Switch

- Ignition OFF, disconnect the harness connector at the S70L Steering Wheel Controls Switch - Left.

- Test for infinite resistance between the control circuit terminal 2 and ground circuit terminal 7.

- If less than infinite resistance

Replace the S70L Steering Wheel Controls Switch - Left.

- If infinite resistance

- Test for 1.0k - 1.5k ohms between the control circuit terminal 2 and ground circuit terminal 7 while pressing forward collision alert switch.

- If not between 1.0k - 1.5k ohms

Replace the S70L Steering Wheel Controls Switch - Left.

- If between 1.0k - 1.5k ohms

- All OK.

Lane Departure Warning Switch

- Ignition OFF, disconnect the harness connector at the S48E Multifunction Switch - Center Console.

- Test for infinite resistance between the control circuit terminal 7 and ground circuit terminal 9.

- If less than infinite resistance

Replace the S48E Multifunction Switch - Center Console.

- If infinite resistance

- Test for 3.8k - 5.8k ohms between the control circuit terminal 7 and ground circuit terminal 9 while pressing the lane departure warning switch.

- If not between 3.8k - 5.8k ohms

Replace the S48E Multifunction Switch - Center Console.

- If between 3.8k - 5.8k ohms

- All OK.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Accessory Switch Replacement (Encore) , Accessory Switch Replacement (Encore)

- Cruise Control Switch Replacement

- Control Module References for frontview camera module replacement, programming, and setup.

SYMPTOMS - OBJECT DETECTION

NOTE: The following steps must be completed before using the symptom tables:

- Perform the Diagnostic System Check - Vehicle before using the Symptom List in order to verify that all of the following are true:

- There are no DTCs set.

- The control modules can communicate via the serial data link.

NOTE: The rear vision camera does not communicate on the serial data bus.

- Review the system operation in order to familiarize yourself with the system functions. Refer to Object Detection Description and Operation (Rearvision Camera, UVC), Object Detection Description and Operation (Rear Park Assist, UD7), Object Detection Description and Operation (Side Blind Zone Alert, UFT), Object Detection Description and Operation (Rear Cross Traffic Alert, UFG).

Visual/Physical Inspection

- Inspect for aftermarket devices which may affect the operation of the system. Refer to Checking Aftermarket Accessories .

- Inspect the easily accessible or visible system components for obvious damage or conditions which may cause the symptom.

- Make sure the parking assist sensors located on the vehicle front and rear bumper are clear. Remove any snow, mud or ice that is blocking the sensors.

Intermittent

Faulty electrical connections or wiring may be the cause of intermittent conditions. Refer to Testing for Intermittent Conditions and Poor Connections .

Symptom List

- Lane Departure Warning System Malfunction

- Parking Assist System Malfunction

- Rear Vision Camera System Malfunction

Front view camera module malfunction (forward collision alert - UEU)

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

Diagnostic Fault Information

.jpg)

Circuit/System Description

The forward collision alert system is controlled by the front view camera module mounted on the windshield.

The forward collision alert system is always active and operates at speeds above 40 km/h (25 mph). When the system detects a vehicle in the path ahead, the green vehicle ahead alert indicator in the instrument cluster is illuminated. When approaching another vehicle too rapidly, the collision alert symbol will flash in the instrument cluster and the radio will simultaneously give an audible alert sound. The red collision alert display will stay continuously illuminated if the vehicle ahead remains much too close. These actions are requested by the front view camera module via serial data to the instrument cluster. The forward collision alert switch is part of the left steering wheel controls and is used to adjust the timing sensitivity of the front collision alert system

Diagnostic Aids

Certain factors will affect the operation of the forward collision alert system. Forward collision alert does not warn the driver of any objects that are not detected as a vehicle, like e.g. pedestrians, animals, signs, guard rails, bridges, construction barrels or other stationary or slow moving objects. In some cases the camera may detect a vehicle that is not in the path ahead, or the system may occasionally provide unrealistic alerts. This could respond to a turning vehicle ahead, guard rails, traffic signs, or other stationary objects. This is normal operation, the vehicle does not need service. When the system is operating properly, the green vehicle ahead alert indicator will illuminate on the vehicle direction display when the system detects a vehicle in the path ahead. This indicates that all of the required operating conditions are met. The green vehicle ahead alert indicator will not appear when the system is having difficulty seeing other vehicles on the road or if the view of the front view camera is blocked with mud, dirt, snow, ice, or slush, if the windshield is damaged, or when weather limits visibility, such as while driving in fog, rain, or snow conditions. This is normal operation, the vehicle does not need service.

Additionally, the Front View Camera Disable History can give useful hints about what affected the operation of the lane departure warning system. For the Front View Camera Disable History refer to DTC B1011.

Reference Information

Schematic Reference

Object Detection Schematics (Encore), Object Detection Schematics (Encore)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS- INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

Description and Operation

Object Detection Description and Operation (Rearvision Camera, UVC), Object Detection Description and Operation (Rear Park Assist, UD7), Object Detection Description and Operation (Side Blind Zone Alert, UFT), Object Detection Description and Operation (Rear Cross Traffic Alert, UFG)

Electrical Information Reference

- Circuit Testing

- Connector Repairs

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

Scan Tool Reference

Control Module References for scan tool information

Circuit/System Verification

NOTE: Refer to Diagnostic Aids before performing Circuit/System Verification

- Ignition ON.

- Verify the scan tool Forward Collision Alert Function Status parameter is Off, Disabled, Not Ready To Assist or Ready To Assist.

- If the parameter is Malfunction

Refer to Circuit/System Testing - Frontview Camera Module Malfunction

- If the parameter is not Malfunction

- Verify the driver information center displays and adjusts forward collision alert setting while repeatedly pressing and releasing the forward collision switch. The setting should cycle between far, medium, near, and off.

- If the display does not change

Refer to Circuit/System Testing - Forward Collision Alert Switch Malfunction.

- If the display changes

- Verify the K109 Frontview Camera Module has good visibility to the road ahead.

- If visibility is poor

Clean windshield

- If visibility is good

- All OK.

Circuit/System Testing

NOTE: You must perform the Circuit/System Verification before proceeding with Circuit/System Testing.

Frontview Camera Module Malfunction

- Ignition ON.

- Verify no DTCs are set.

- If DTCs are set

Diagnose and repair DTCs. Refer to Diagnostic Trouble Code (DTC) List - Vehicle .

- If no DTCs are set

- Ignition OFF and all vehicle systems OFF. It may take up to 2 min for

all vehicle systems to power down.

Disconnect the harness connector at the K109 Frontview Camera Module.

- Test for less than 10 ohms between the ground circuit terminal 1 and ground.

- If 10 ohms or greater

- Ignition OFF.

- Test for less than 2 ohms in the ground circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, repair the open/high resistance in the ground connection.

- If less than 10 ohms

- Verify a test lamp illuminates between the B+ circuit terminal 3 and ground.

- If the test lamp does not illuminate and the circuit fuse is good

- Ignition OFF.

- Test for less than 2 ohms in the B+ circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, verify the fuse is not open and there is voltage at the fuse.

- If the test lamp does not illuminate and the circuit fuse is open

- Ignition OFF.

- Test for infinite resistance between the B+ circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance, replace the K109 Frontview Camera Module.

- If the test lamp illuminates

- Ignition ON.

- Test for less than 1 V between the signal circuit terminal 10 and ground.

- If 1 V or greater

- Disconnect the harness connector at S70L Steering Wheel Controls Switch - Left.

- Test for less than 1V between the signal circuit terminal 10 and ground.

- If 1V or greater, repair the short to voltage on the signal circuit.

- If less than 1 V

- Ignition OFF.

- Test for infinite resistance between the signal circuit terminal 10 and ground with the forward collision alert switch not pressed

- If less than infinite resistance

- Disconnect the harness connector at the S70L Steering Wheel Controls Switch - Left.

- Test for infinite resistance between the signal circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance test or replace the S70L Steering Wheel Controls Switch - Left.

- If infinite resistance

- Test for 1.2k-1.4k ohms between the signal circuit terminal 10 and ground with the forward collision alert switch pressed.

- If not between 1.2k-1.4k ohms

- Disconnect the harness connector at the S70L Steering Wheel Controls Switch - Left

- Test for less than 2 ohms in the signal circuit from end to end.

- If greater than 2 ohms

Repair the open/high resistance in the circuit.

- If 2 ohms or less

- Test or replace the S70L Steering Wheel Controls Switch - Left.

- If between 1.2k-1.4k ohms

- Connect the harness connector of the S70L Steering Wheel Controls Switch - Left and K109 Frontview Camera Module.

- Verify the scan tool Forward Collision Alert Function Status parameter is Off, Disabled, Not Ready To Assist or Ready To Assist.

- If parameter is Malfunction

Replace K109 Frontview Camera Module.

- If parameter is not Malfunction

- All OK.

Forward Collision Alert Switch Malfunction

- Ignition OFF and all vehicle systems OFF. It may take up to 2 min for all vehicle systems to power down.

Disconnect the harness connector at the S70L Steering Wheel Controls Switch - Left.

- Test for less than 5 ohms between the ground circuit terminal 7 and ground.

- If 5 ohms or greater

- Ignition OFF.

- Test for less than 2 ohms in the ground circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, repair the open/high resistance in the ground connection.

- If less than 5 ohms

- Ignition ON.

- Verify the scan tool Lane Departure Warning Switch Status parameter is Open.

- If not Open

- Ignition OFF, disconnect the harness connector at the K109 Frontview Camera Module.

- Test for infinite resistance between the signal circuit terminal 2 and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance, replace the K109 Frontview Camera Module.

- If Open

- Install a 3 A fused jumper wire between the signal circuit terminal 2 and the ground circuit terminal 7.

- Verify DTC B356A 02 sets.

- If DTC does not set

- Ignition OFF, remove the jumper wire, disconnect the harness connector at the K109 Frontview Camera Module, ignition ON.

- Test for less than 1 V between the signal circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V

- Test for less than 2 ohms in the signal circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K109 Frontview Camera Module.

- If DTC sets

- Test or replace the S70L Steering Wheel Controls Switch - Left.

Component Test

Switch Static Test

- Ignition OFF, disconnect the harness connector at the S70L Steering Wheel Controls Switch - Left.

- Test for infinite resistance between the control circuit terminal 2 and ground circuit terminal 7.

- If less than infinite resistance

Replace the S70L Steering Wheel Controls Switch - Left.

- If infinite resistance

- Test for 1.0k - 1.5k ohms between the control circuit terminal 2 and ground circuit terminal 7 while pressing forward collision alert switch.

- If not between 1.0k - 1.5k ohms

Replace the S70L Steering Wheel Controls Switch - Left.

- If between 1.0k - 1.5k ohms

- Test for 3.8k - 5.8k ohms between the control circuit terminal 2 and ground circuit terminal 7 while pressing lane departure warning switch.

- If not between 3.8k - 5.8k ohms

Replace the S70L Steering Wheel Controls Switch - Left.

- If between 3.8k - 5.8k ohms

- All OK.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Cruise Control Switch Replacement

- Control Module References for frontview camera module replacement, programming and setup.

Parking assist system malfunction

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

Circuit/System Description

The ultrasonic parking assist system is designed to identify and notify the driver of an object in the vehicle's path when reversing at speeds of less than 8 km/h (5 MPH). The distance and location of the object is determined by four object sensors located in the rear bumper. The parking assist system will notify the driver using an audible signal through the radio.

Diagnostic Aids

When the "Park Assist Off", "Park Asst Blocked See Owners Manual", or "Park Assist Blocked See Owners Manual" message is displayed in the DIC the disable reason is stored in the Park Assist Disable History.

The scan tool Park Assist Disable History parameters are a list of the seven previous reasons the parking assist system was disabled. These parameters may help in the diagnosis of an intermittent concern or a customer concern which is the result of normal system operation. The following is a brief description of potential causes which may aid in diagnosis:

- Manual Disable - The parking assist system has been disabled by the vehicle operator through the audio system personalization menu.

- Hitch/Object Attached - The front and rear parking assist control module is detecting an object that is attached to the vehicle. Common items such as a hitch receiver, trailer, or a bicycle rack may cause this concern. Additionally, damage to the rear of the vehicle or a misaligned sensor may cause this concern. If the vehicle is damaged in a manner that causes the sensor to detect the bumper itself, the front and rear parking assist control module will interpret this as an attached object and disable the system. Carefully inspect the bumper, bumper mounting surface, and sensor retainers before continuing with normal diagnosis. After the detected cause has been addressed the vehicle must be driven at speed greater than 40 km/h (25 MPH).

- Reverse Overspeed - The vehicle is travelling too fast in reverse at speeds of greater than 8 km/h (5 MPH).

- Inhibit - The front and rear parking assist control module has lost or received invalid GMLAN signal(s).

- Sensor Disturbance - An outside interference is causing sensor movement. Such interference may be caused by a heavy pounding, like that of a nearby jackhammer, or large changes in pressure, such as a large truck's air brakes.

- Sensor Ring Time - If the sensor fails its own diagnostic initialization the front and rear parking assist control module will set this error. After the detected cause has been addressed the vehicle must be driven at speed greater than 40 km/h (25 MPH). The following is a list of reasons this cause may have set:

- One or more of the sensors may be blocked by snow, mud, ice, or other debris. This might happen after going through a car wash in cold weather.

- Silicone insulator surrounding sensor may be missing, cut, or twisted.

- Improperly installed sensor, sensor may be crooked due to a tight wire harness.

- One or more of the sensors may be scratched or the paint may be chipped.

- Excessive paint thickness on a sensor may cause an excessive sensor ring time. When replacing or refinishing a sensor, do not apply an excessive amount of paint or clear coat.

Reference Information

Schematic Reference

Object Detection Schematics (Encore), Object Detection Schematics (Encore)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

Description and Operation

Object Detection Description and Operation (Rearvision Camera, UVC), Object Detection Description and Operation (Rear Park Assist, UD7), Object Detection Description and Operation (Side Blind Zone Alert, UFT), Object Detection Description and Operation (Rear Cross Traffic Alert, UFG)

Electrical Information Reference

- Circuit Testing

- Connector Repairs

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

Scan Tool Reference

Control Module References for scan tool information

Circuit/System Testing

Manual Transmission

- Ignition ON, transmission in REVERSE, verify the engine control module (ECM) scan tool Reverse Position Switch parameter is Active.

- If not the specified value, refer to Backup Lamps Malfunction (Manual Transmission) , Backup Lamps Malfunction (Automatic transmission)

- Verify the scan tool Park Assist System Status parameter displays Enable.

NOTE: After completing the next step the vehicle might need to be driven in the forward direction at speed greater than 40 km/h (25 MPH).

- If not the specified values, refer to Diagnostic Aids and the scan tool Park Assist Disable History parameters to determine the cause of the inhibit.

- If all tests normal, replace the K41 Front and Rear Parking Assist Control Module.

Automatic Transmission

- Ignition ON, transmission in REVERSE, verify the scan tool Park Assist System Status parameter displays Enable.

NOTE: After completing the next step the vehicle might need to be driven in the forward direction at speed greater than 40 km/h (25 MPH).

- If not the specified values, refer to Diagnostic Aids and the scan tool Park Assist Disable History parameters to determine the cause of the inhibit.

- If all tests normal, replace the K41 Front and Rear Parking Assist Control Module.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

Control Module References for front and rear parking assist control module replacement, programming and setup

Rear vision camera system malfunction

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

Diagnostic Fault Information

.jpg)

Circuit/System Description

When the transmission is placed into REVERSE, a 12 V signal is sent to the rearview camera indicating that camera operation is requested. Ignition voltage and ground are supplied to the rearview camera. The rearview camera sends video information to the radio through a video signal + and a video signal - circuit. A grounded shielding also wraps the video signal circuits to reduce electronic interference which may degrade the video signal and cause a distorted or otherwise degraded image.

Diagnostic Aids

A poor video image can be caused by ice, snow, and mud buildup on the lens of the rearview camera. Also, extreme lighting conditions can affect performance, such as operating in the dark or with bright sunlight shining on the camera. Extreme high or low temperatures can also affect the image quality. An open in the shield of the video signal circuit can also cause a distorted screen.

Reference Information

Schematic Reference

Object Detection Schematics (Encore), Object Detection Schematics (Encore)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

Description and Operation

Object Detection Description and Operation (Rearvision Camera, UVC), Object Detection Description and Operation (Rear Park Assist, UD7), Object Detection Description and Operation (Side Blind Zone Alert, UFT), Object Detection Description and Operation (Rear Cross Traffic Alert, UFG)

Electrical Information Reference

- Circuit Testing

- Connector Repairs

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

Circuit/System Verification

- Ignition ON.

- Verify that DTC B2545 is not set.

- If the DTC is set

Refer to DTC B2545 .

- If the DTC is not set

- Verify there is no debris on the rearview camera lens and that the bezel and bezel seal are not damaged.

- If debris are found on the lens

Clean the lens. If the lens, bezel, or bezel seal are damaged, replace as necessary.

- If no debris on the lens

- Engine running, transmission in REVERSE.

- Verify the backup lamps are On.

- If the backup lamps are not ON

Refer to Backup Lamps Malfunction (Manual Transmission) , Backup Lamps Malfunction (Automatic transmission) .

- If the backup lamps are ON

- Engine running, transmission in REVERSE.

- Verify a clear rear vision image is displayed on the radio.

- If a clear image is not displayed

Refer to Circuit/System Testing

- If a clear image is displayed

- All OK.

Circuit/System Testing

NOTE: Circuit/System Verification must be performed before Circuit/System Testing.

- Ignition OFF and all vehicle systems OFF, disconnect the harness connector at the B87 Rearview Camera. It may take up to 2 min for all vehicle systems to power down.

- Test for less than 10 ohms between the ground circuit terminal 5 and ground.

If 10 ohms or greater

- Test for less than 2 ohms in the ground circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, repair the open/high resistance in the ground connection.

- If less than 10 ohms

- Ignition ON.

- Verify a test lamp illuminates between the ignition circuit terminal 6 and ground.

- If the test lamp does not illuminate and the circuit fuse is good

- Ignition OFF.

- Test for less than 2 ohms in the ignition circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, verify the fuse is OK and there is voltage at the fuse.

- If the test lamp does not illuminate and the circuit fuse is open

- Ignition OFF.

- Test for infinite resistance between the ignition circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance, refer to Power Mode Mismatch .

- If the test lamp illuminates

- Engine running, park brake applied, transmission in REVERSE.

- Verify a test lamp illuminates between the control circuit terminal 3 and ground.

- If the test lamp does not illuminate

- Ignition OFF, disconnect the X7 harness connector at the K9 Body Control Module and remove both E5 Backup Lamps.

- Test for infinite resistance between the control circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance

- Test for less than 2 ohms in the control circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K9 Body Control Module.

- If the test lamp illuminates

- Ignition OFF, disconnect the X4 harness connector at the A11 Radio, ignition ON.

- Test for less than 1 V between the signal circuit terminal listed below and ground:

- B87 Rearview Camera signal (+) circuit terminal 1.

- B87 Rearview Camera signal (-) circuit terminal 4.

- If 1 V or greater